Application examples

In over 20 years of Wiest AG, many exciting projects have been created using our products. Here is a selection of applications for our LaserLAB, RotoLAB and GripLAB products.

Case Studys

See our application examples here

- All

- Automation technology

- Automotive engineering

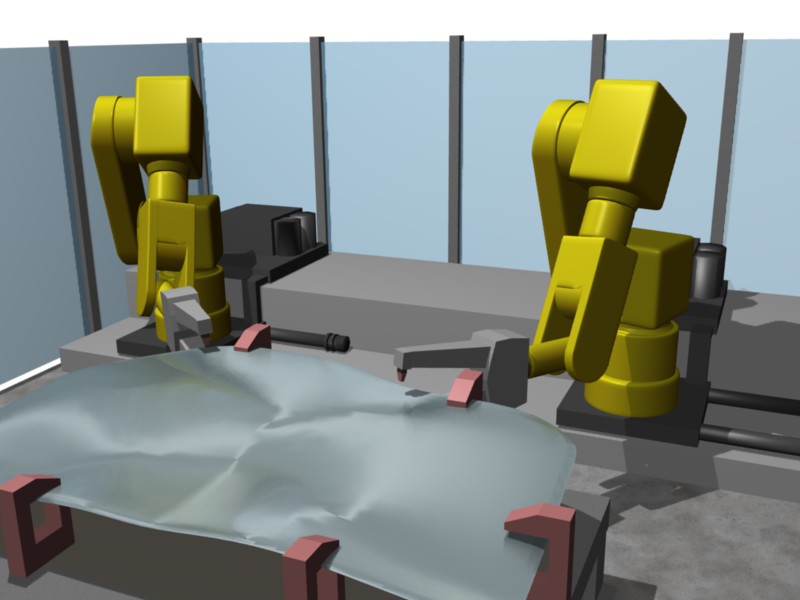

- Bonding and beading

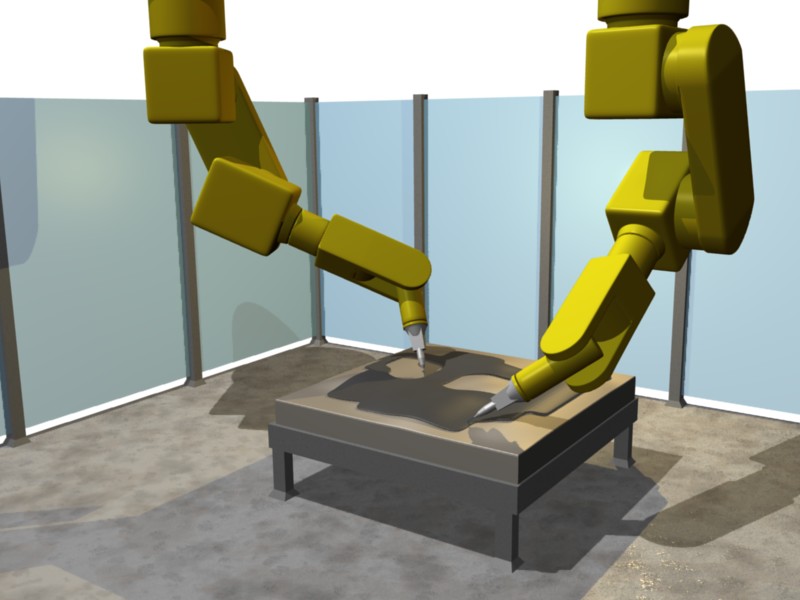

- Drilling and milling

- Handling and Assembly

- Line-welding

- Other

- Plant engineering

- Seam sealing

- Spot welding

- Underbody protection

- Waterjet cutting

Fast commissioning of offline programmes

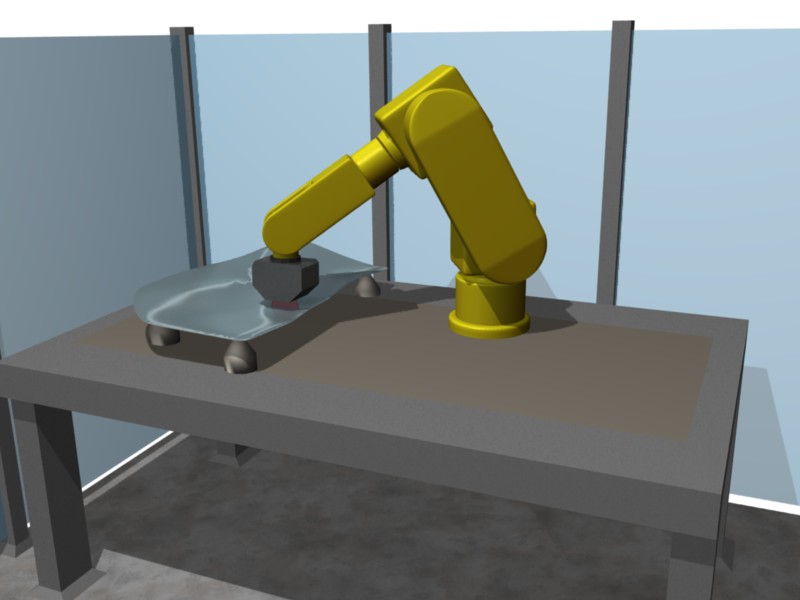

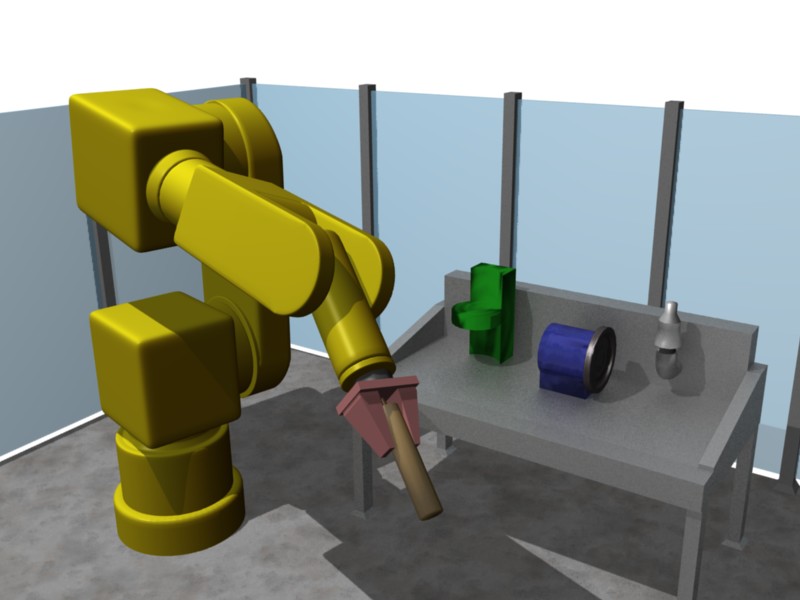

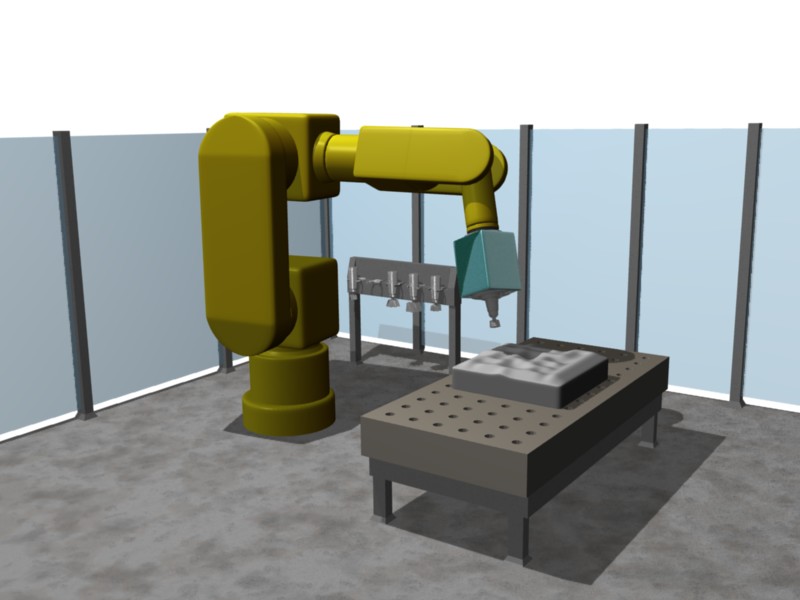

Robot cell for quality inspection

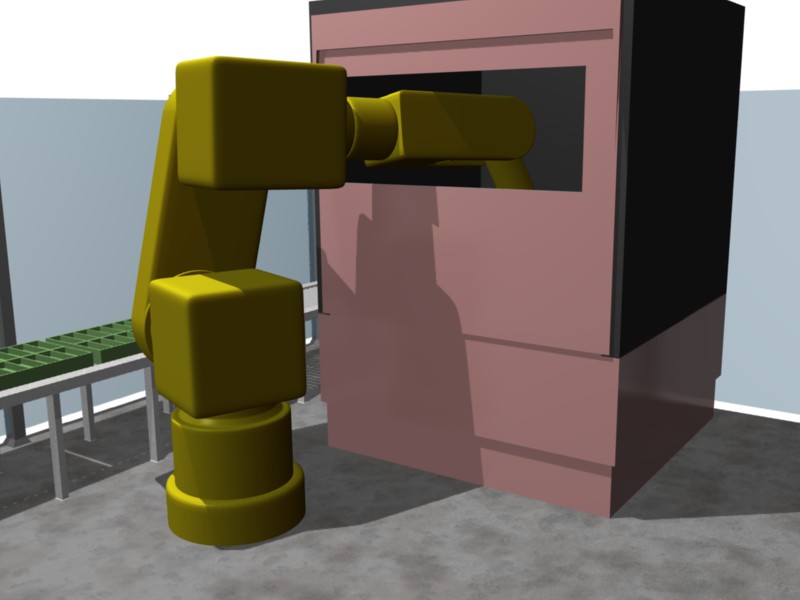

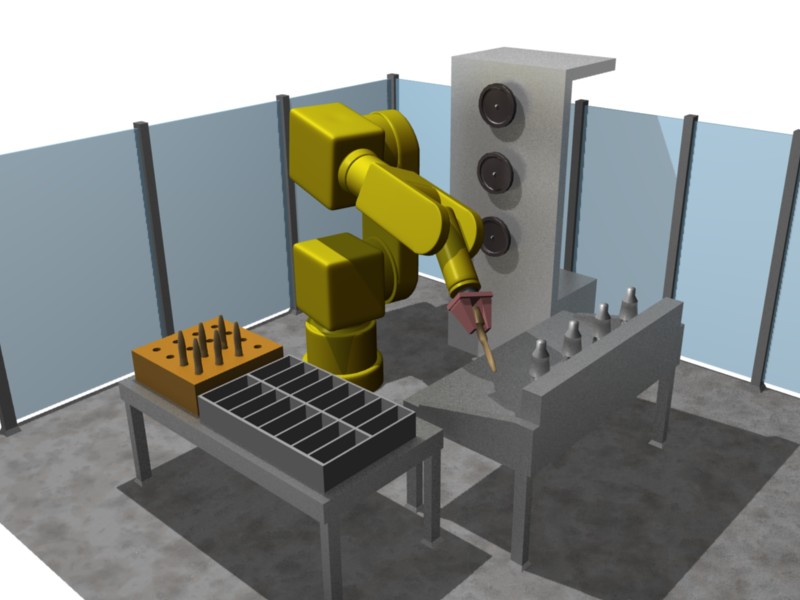

Difficult to access machine loading

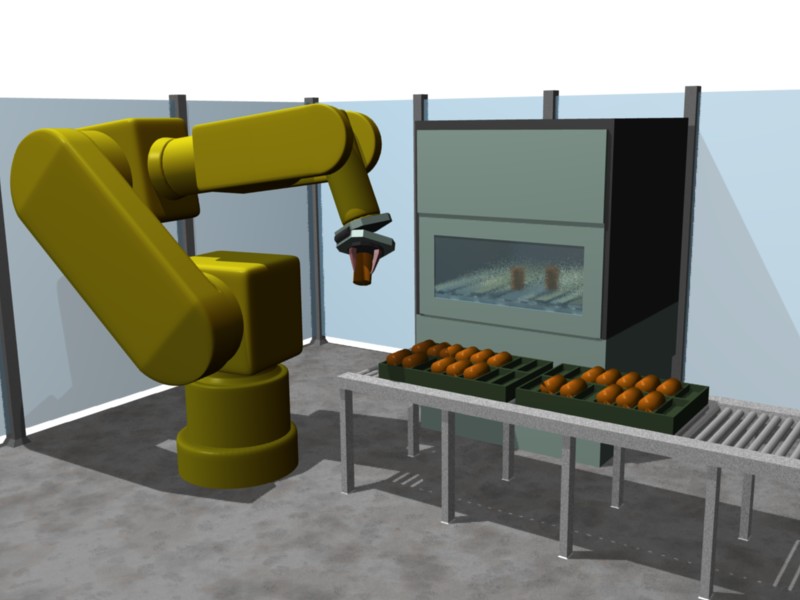

Machine loading with sensitive gripper

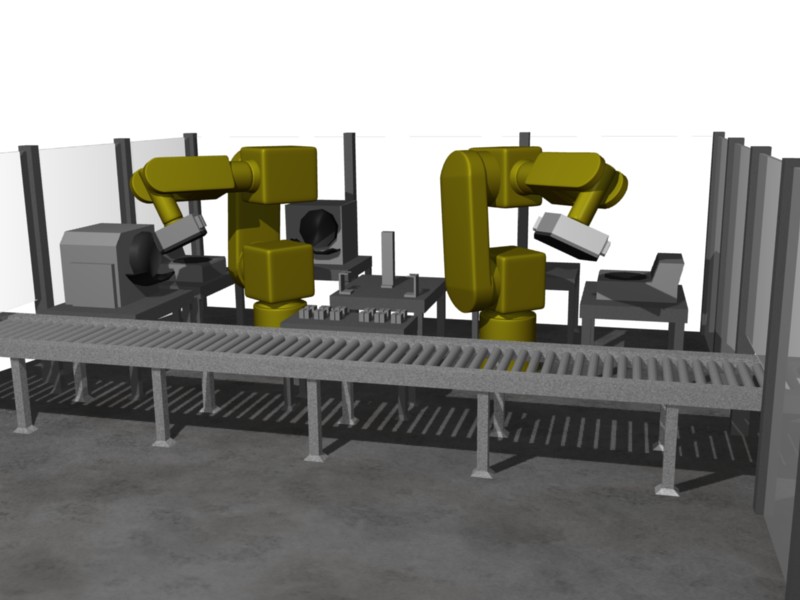

Completely secured production line

Machining castings with many path points

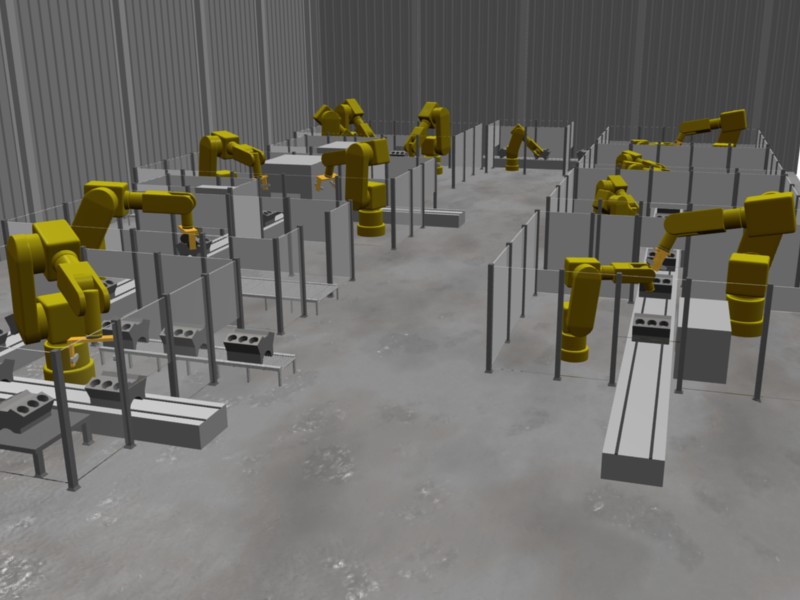

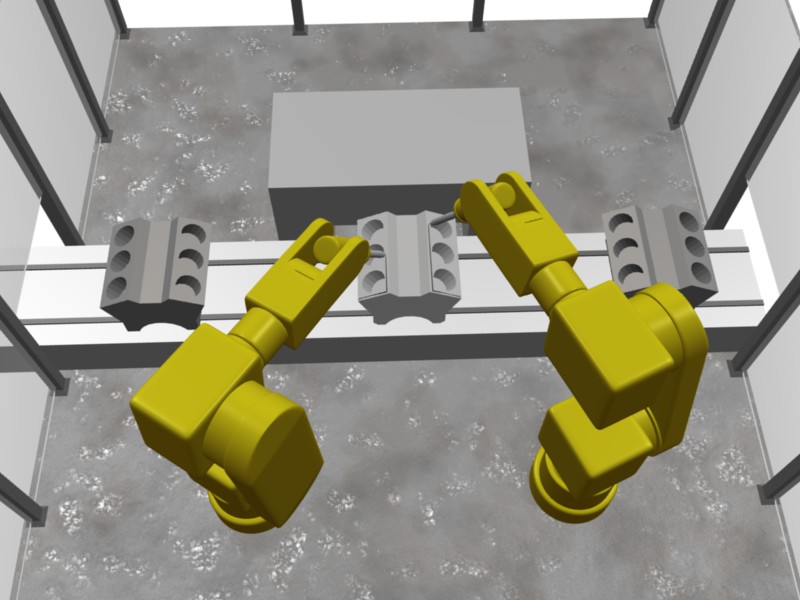

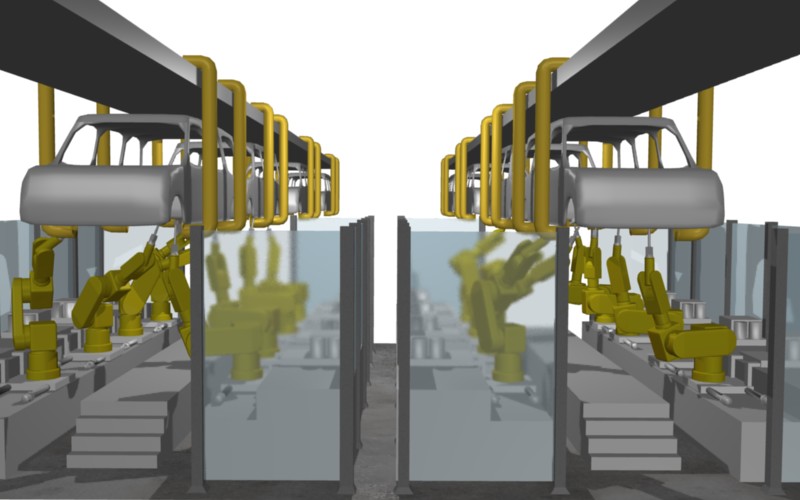

Cloning of milling cells

Safeguarding of complex machining cells

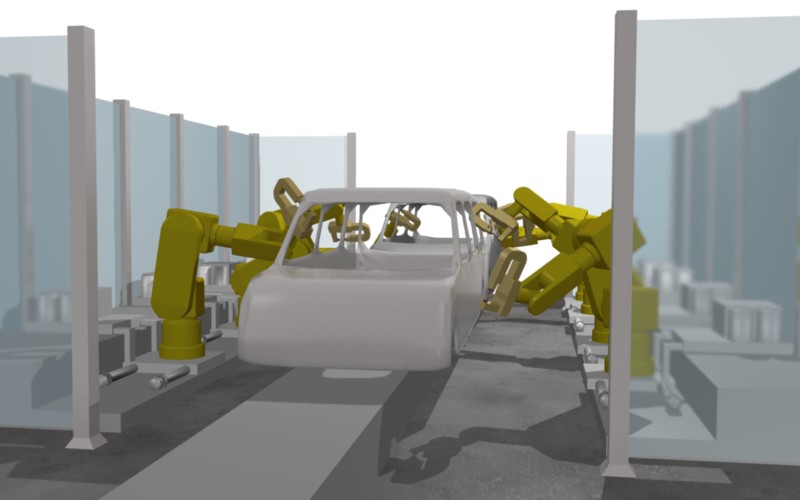

Spot welding in body-in-white

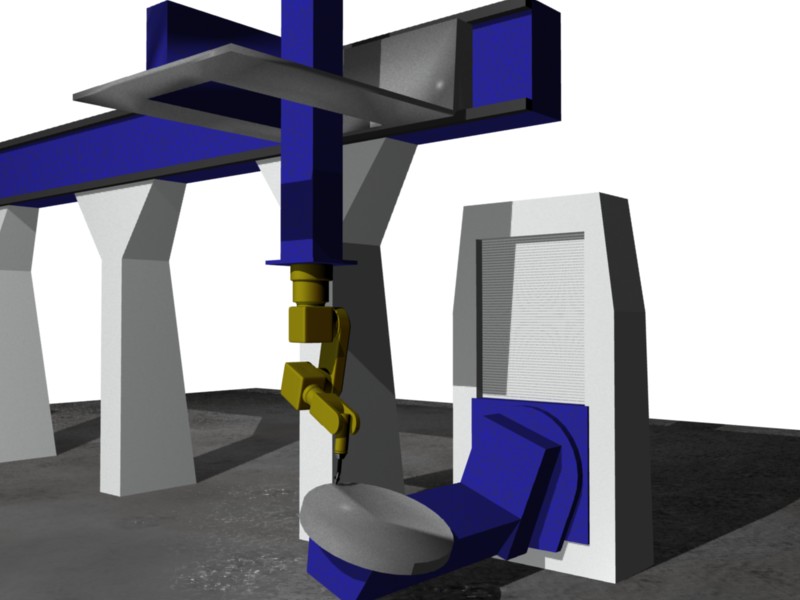

Precise thrust direction for milling applications

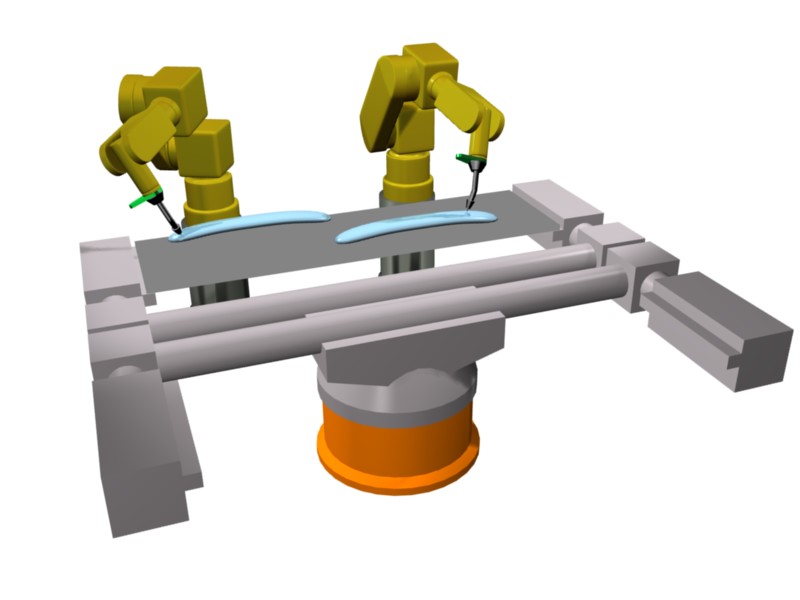

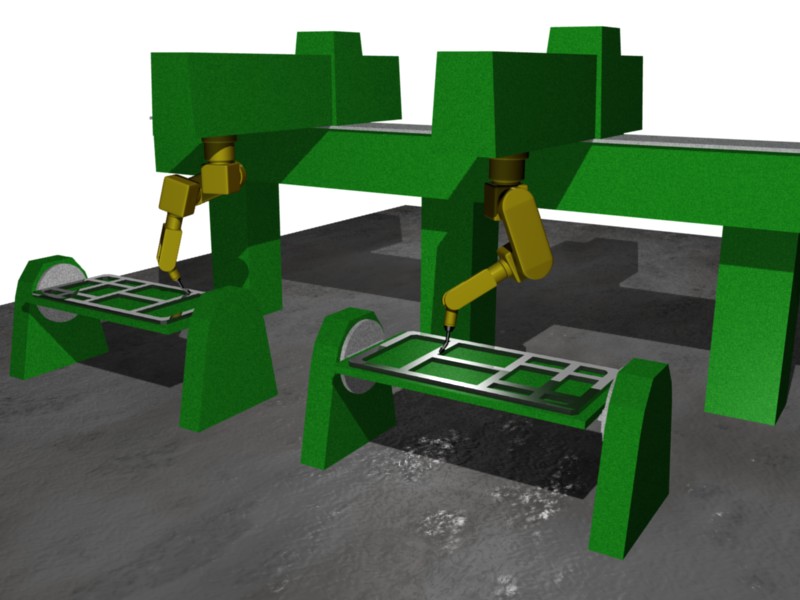

Path welding with manual jig change

Calibrating a vision system into car frame

Set-up time optimization and fast maintenance after crash

Seam sealing and underbody protection

Sealant application from 0.5 mm distance

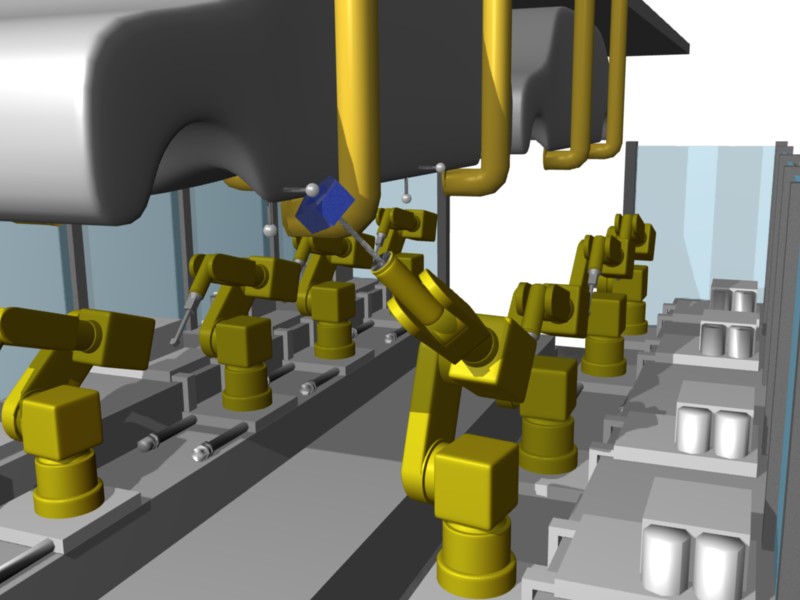

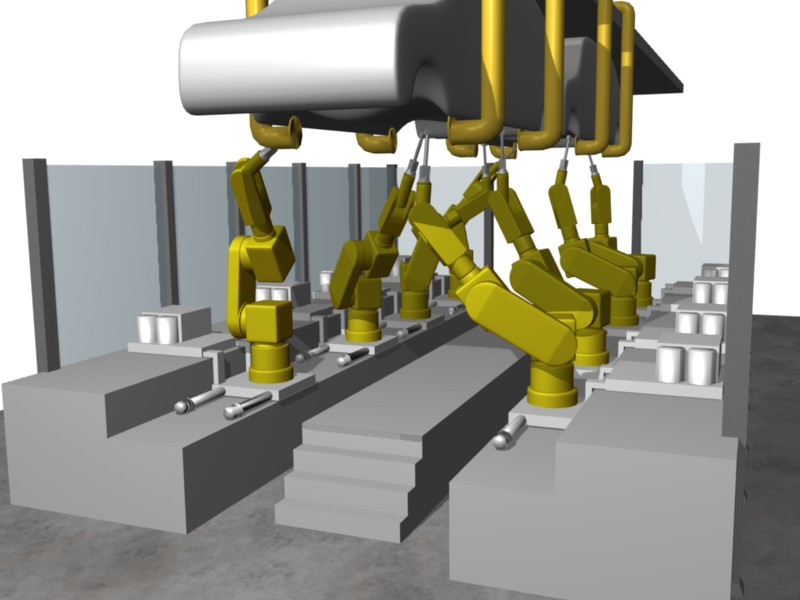

Offline programming of 12 axes

Mastering of MOTOMAN robots

Cloning of production lines

Are you interested? We will be happy to advise you.

Your personal contact will be happy to show you on site how your company can benefit from our solutions.

Services

Our customer support team is here to help you. Please do not hesitate to contact us.

We can help you find the causes, advise on possible solutions and offer complete solutions with customised measurement programmes and systems. Contact us.

Our experienced team of robotics specialists will work hand in hand with you to efficiently implement cell calibration solutions and train your staff to use the systems.

Complete measurement data logs allow optimal remote support by our experts. Our support is also available for spontaneous problems via e-mail, telephone, video call or on-site.