Application of sealant at a spacing of only 0.5 mm

When applying sealant to the cylinder head of an engine, the nozzle moves only 0.5 mm above the surface.

Advantages

Benefit for the client

By measuring with LaserLAB, the customer is able to use calculated paths that run exactly at a defined distance from the workpiece surface.

Case

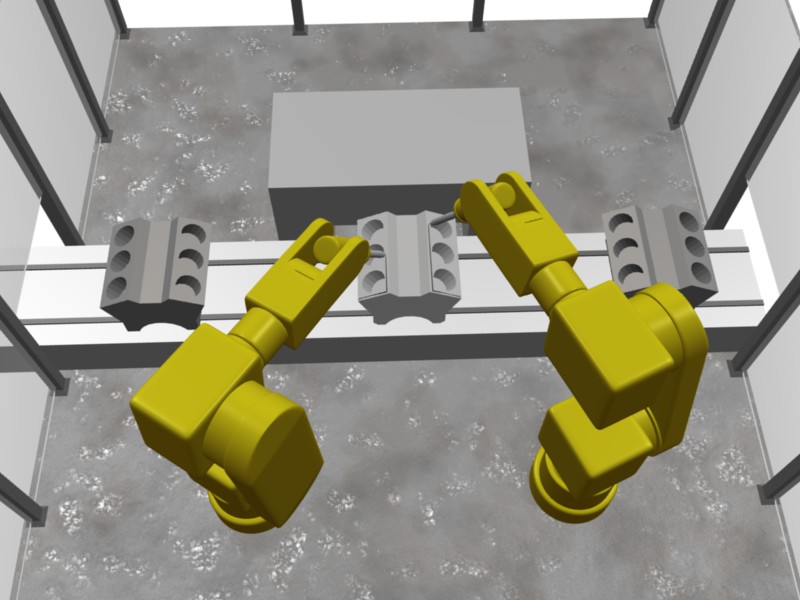

Cell description

Inside the cell, two ABB 1400 robots apply sealant to the cylinder head of an engine. The nozzle moves only 0.5 mm above the surface of the engine. Only the first point of the path is taught in the robot programmes. All other points will be calculated from this.

Task

To keep the calculation as simple as possible, a work object is placed on the inclined surface of the cylinder head. This work-piece must be very accurately aligned with the cylinder head surface, as the robot must constantly maintain the 0.5 mm to the workpiece, and only a tolerance of +/- 0.1 mm is allowed.

Implementation

A master part was created from an engine block by attaching four measuring rods. The master motor was accurately measured with the LaserLAB. The coordinate system for the work object on the cylinder head surface was generated from the measurement. This coordinate system makes it very easy to specify points in the X-Y plane. Z determines the distance from the surface and remains constant throughout the machining process.

Measuring the work piece with the usual manual methods simply does not provide the required accuracy.

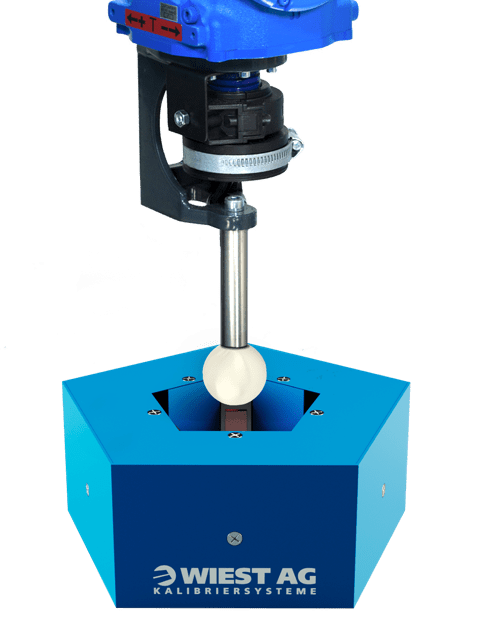

Products

These Wiest products were used:

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Wenden Sie sich an unser Support-Team bei allen technischen Fragen

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order