Machine loading with sensitive gripper

In a compact cell, it is necessary to work with a very complex gripper that cannot simply be replaced by a spare gripper in the event of a crash.

Wiest advantages

Customer benefits

The measurement provides the customer with a backup of their hardware. Hardware recovery is now possible at any time by re-measuring after a crash or gripper replacement. There is no need to spend time re-teaching, the system is secure.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

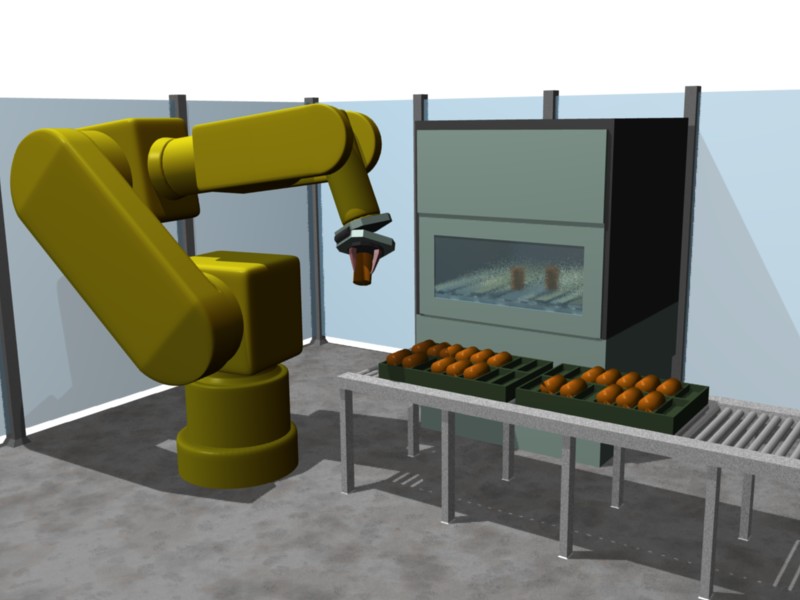

Cell description

The customer uses a KUKA KR125 to insert throttle bodies into a CNC machining centre. This is where the surfaces of the housings are milled. The unique aspect of the machine is that it is a very sensitive and complex gripper. This is necessary because the space in the cell is so limited that a more robust gripper cannot be used. Among other things, the gripper is folded in for certain movements so that the robot can reach its positions.

Task

At the time of commissioning, the plant was processing five different types of enclosures. In total, however, the cell is designed for around 120 types. The enormous variety of types also increases the number of programme items. Due to the complexity of the gripper, it cannot simply be replaced by a spare gripper in the event of a crash, as it is difficult to manufacture a mechanically identical gripper. This would stop production for several days while the programmes were re-teached.

Implementation

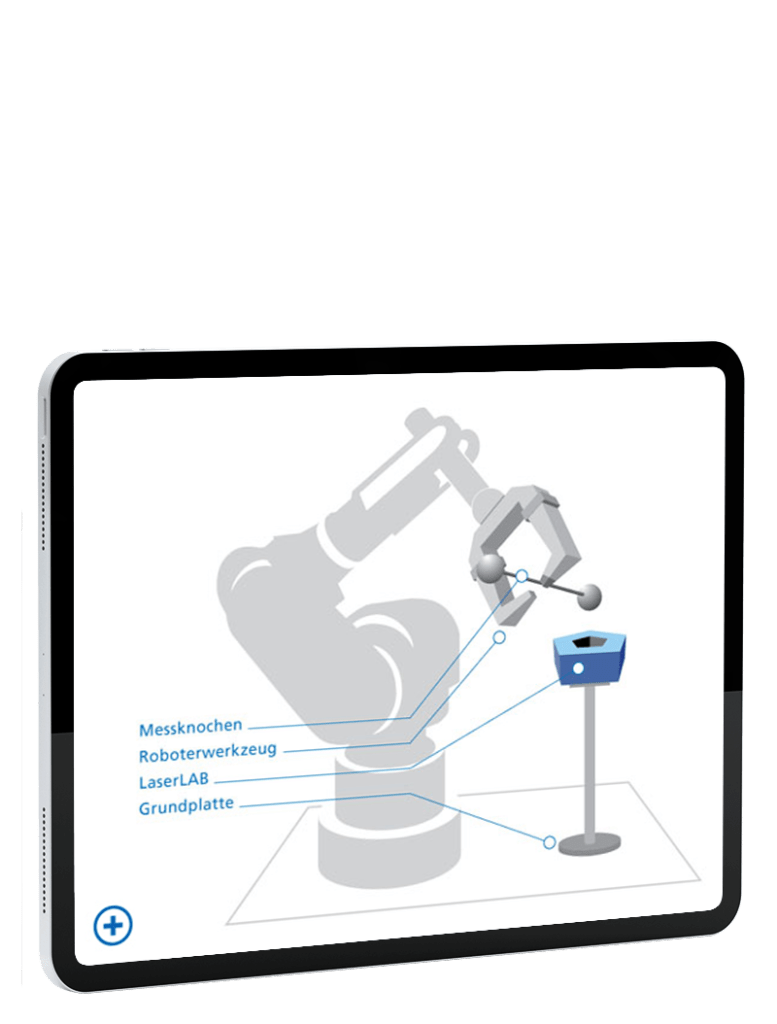

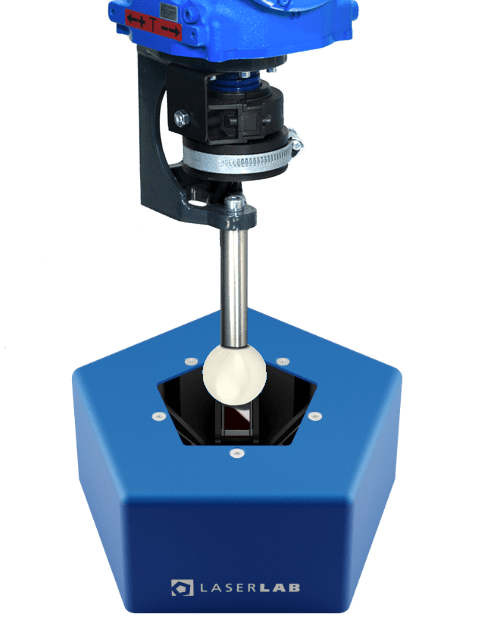

For a measurement, a master component with four measuring balls is inserted into the gripper as far as it will go and the gripper is closed. Now a robot programme only needs to move to five points to measure the balls. The result is the gripper’s new tool frame.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order