Fast commissioning of offline programmes

Fast commissioning of offline programmes In order to avoid having to recreate robot programmes created offline, it is necessary to measure the robots with absolute precision and determine tool and frame data accurately. Wiest advantages Customer benefits The time required to re-teach offline generated programmes has been minimised. The goal of a very short commissioning […]

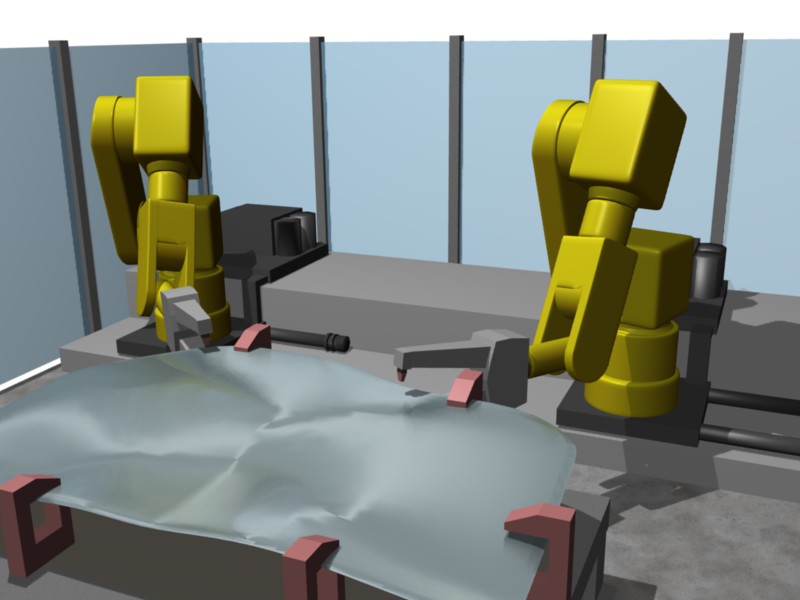

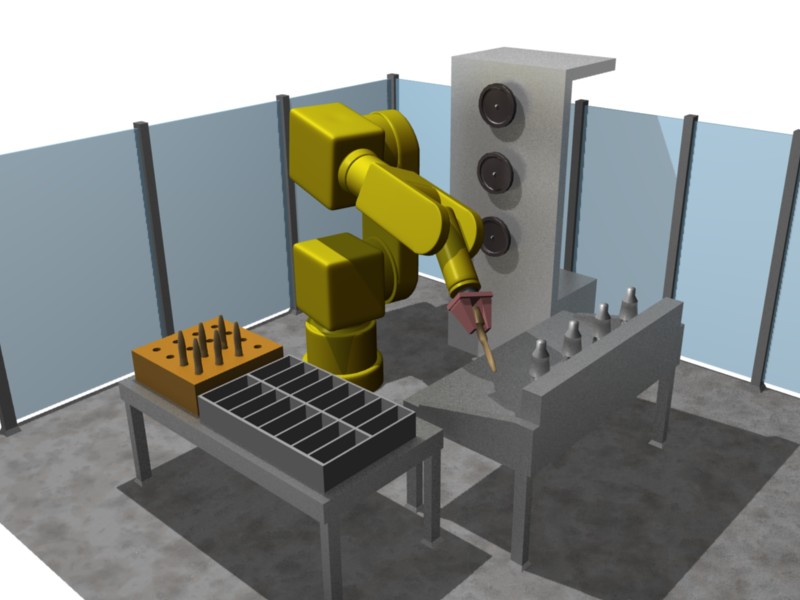

Robot cell for quality inspection

Robot cell for quality inspection When building robotic systems for materials testing, a constant sequence of robot programmes with constant sensor spacing must be ensured. Home Anwendungen WIEST advantages Customer benefits By using LaserLAB, the customer is able to maintain its robot systems, which are sold worldwide, according to a standardised method. Integration on the […]

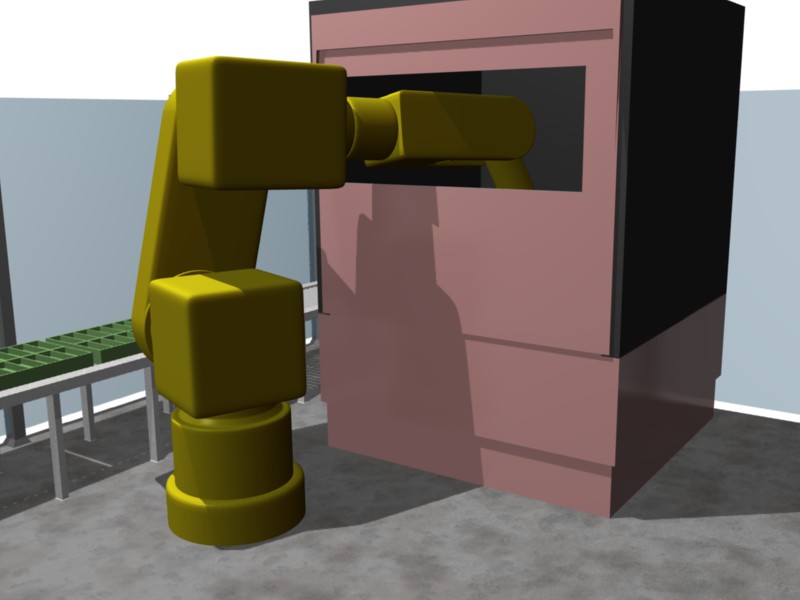

Difficult to access machine loading

Difficult to access machine loading When moving a highly complex, out-of-sight cell, it is essential to avoid a lengthy production stoppage. Home Anwendungen Wiest advantages Customer benefits The deviations that occurred were corrected by the Wiest software, and the line was immediately returned to production. Wiest AG helped the customer reduce a lengthy production stoppage […]

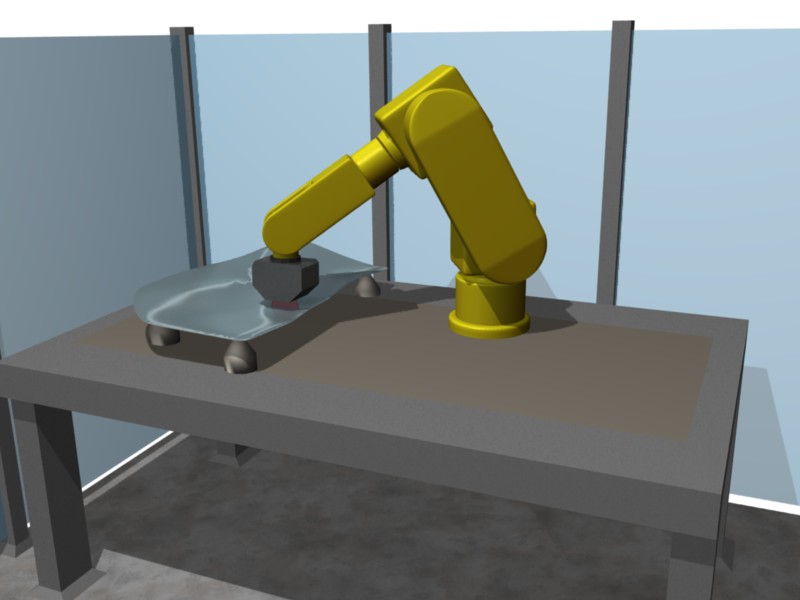

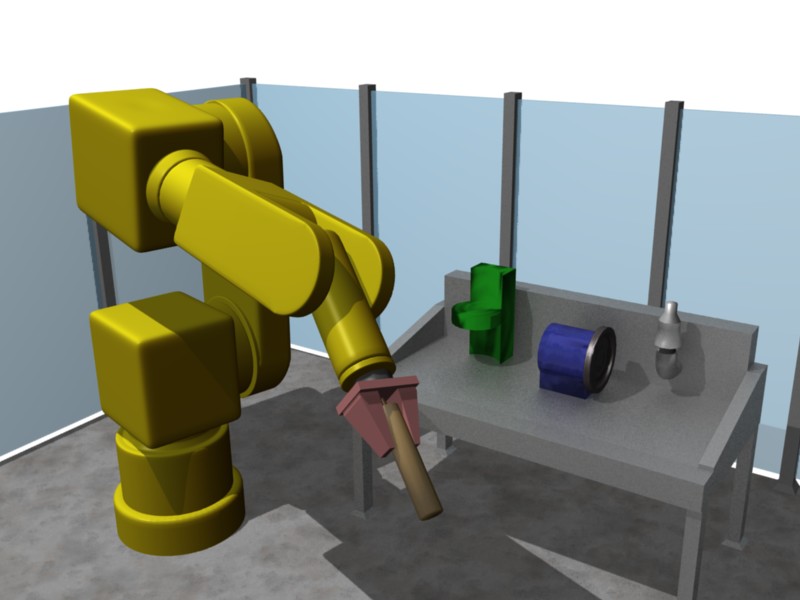

Machine loading with sensitive gripper

Machine loading with sensitive gripper In a compact cell, it is necessary to work with a very complex gripper that cannot simply be replaced by a spare gripper in the event of a crash. Home Anwendungen Wiest advantages Customer benefits The measurement provides the customer with a backup of their hardware. Hardware recovery is now […]

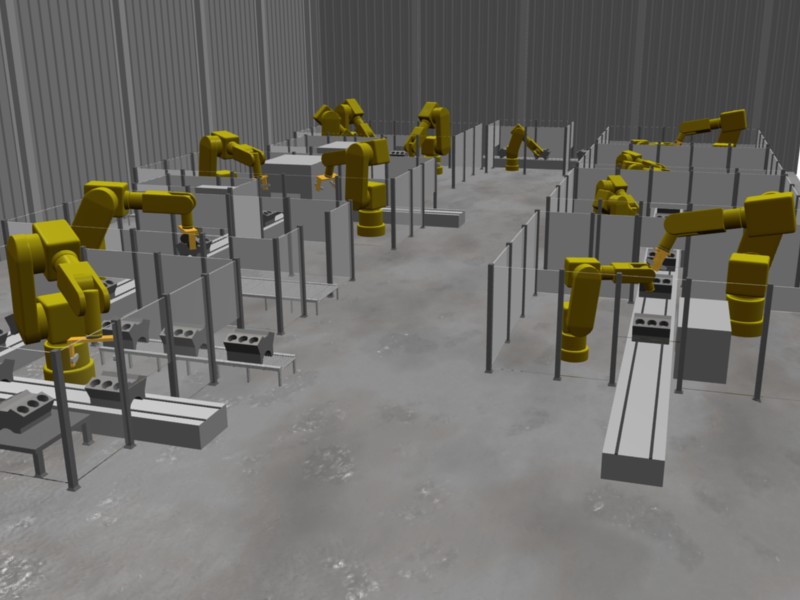

Completely secured production line

Complete safeguarding of the production line To be able to start all robot programmes on a production line from a single point, work objects and tools need to be measured as accurately as possible. Home Anwendungen WIEST advantages Customer benefits The customer has the possibility to calculate the paths of his robots as far as […]

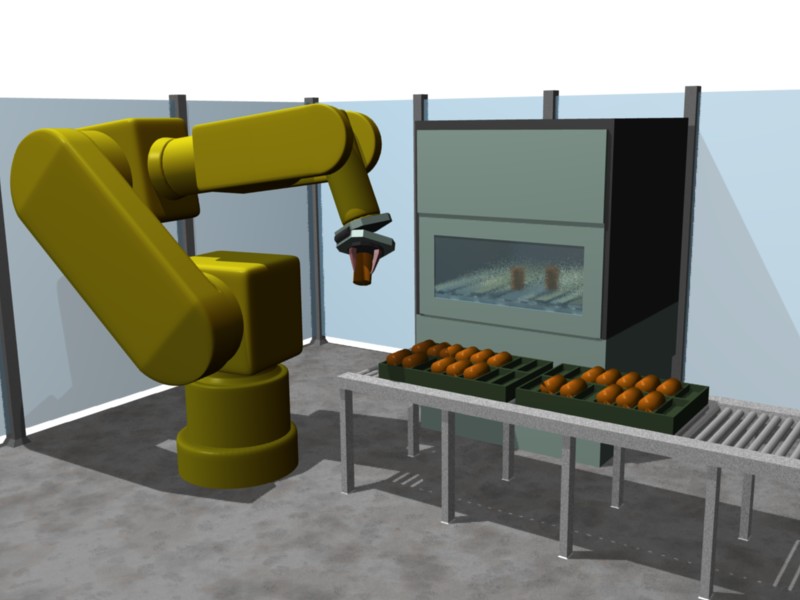

Machining castings with many path points

Machining of castings with many path points In a system for deburring castings, point misalignments occur time and again, resulting in extensive re-teaching. Home Anwendungen Wiest advantages Customer benefits The plant was back in production immediately after the move. By investing in Wiest LaserLAB, the customer has avoided at least one week of production downtime. […]

Cloning of milling cells

Cloning of production lines To avoid having to repeat the complex measurement for a second cell for deburring turbine blades, the robot cell is to be cloned. Home Anwendungen Wiest advantages Customer benefits The programmes of the master cell were easily transferred to the cloned cell. At the same time, both installations could be secured […]

Safeguarding of complex machining cells

Safeguarding of complex machining cells Two absolute-precision robots, which handle endoscopes at a total of eight stations, are to be safe-guarded. Home Anwendungen Wiest advantages Customer benefits By measuring with loop:in, tool:in and base:in, the system is fully secured. It can also be relocated without the need for re-teaching. Integration on the second line without […]

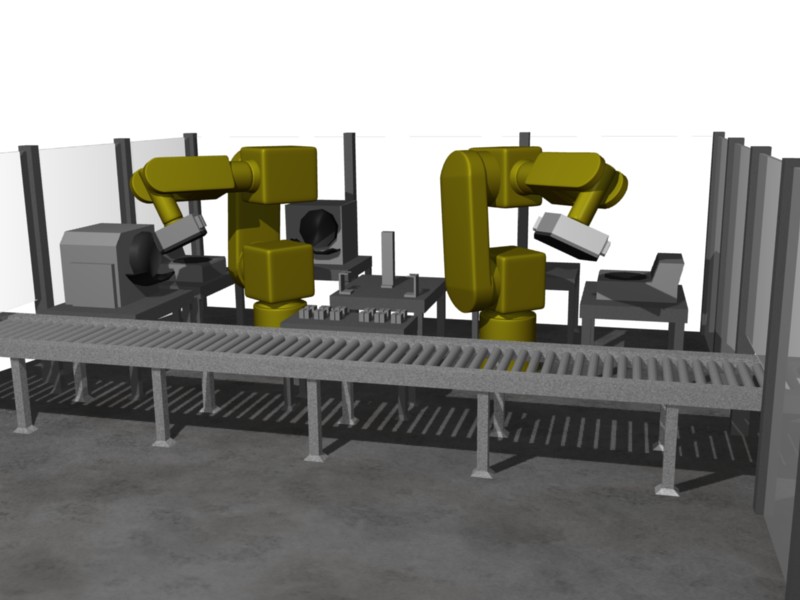

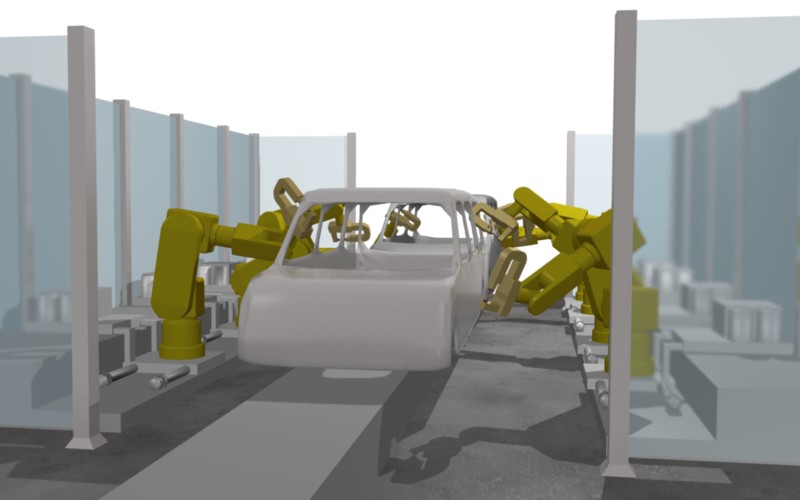

Spot welding in body-in-white

A large car manufacturer operates several welding lines for car bodies. Kuka KR125 robots and Comau H4 with spot-welding guns are used.

The special feature of the production line is that a large number of different models are produced on the same lines, and new models need to be introduced with as little interruption to the running line as possible.

To make matters worse, re-teaching had to be done for all models. However, these were not available at the time of the work. The model may not have appeared until the next shift. If you forgot to stop the line and adjust the robot programmes, the crash happened again.

In addition, the task was to ensure that the Comau robots could be exchanged for new ones. There is no repeatable and reproducible mastering procedure for this type of robot.

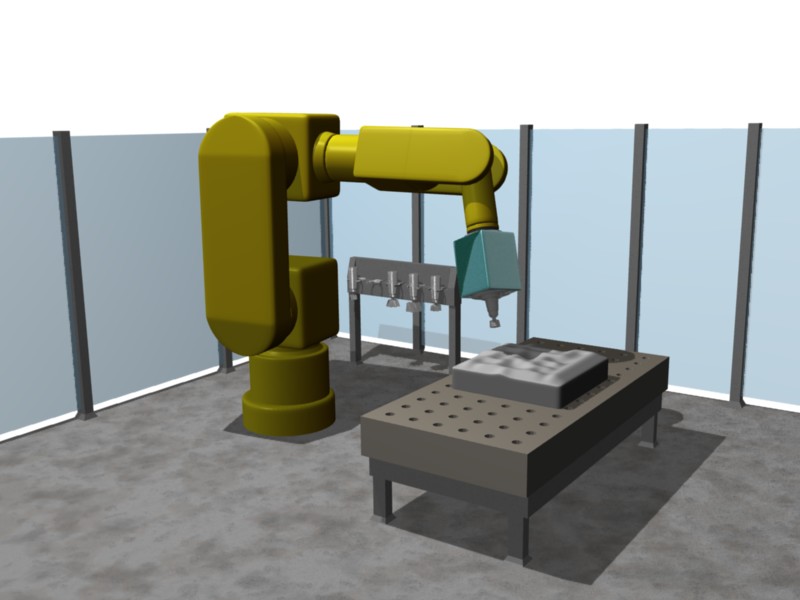

Precise thrust direction for milling applications

Precise thrust direction for milling applications A milling robot is used to produce parts using the rapid prototyping method. Home Anwendungen Wiest advantages Customer benefits Using a LaserLAB and tool:in, the thrust direction of the milling tool was determined with high precision within a few minutes. Manual alignment of quaternions is a thing of the […]