Complete safeguarding of the production line

To be able to start all robot programmes on a production line from a single point, work objects and tools need to be measured as accurately as possible.

WIEST advantages

Customer benefits

The customer has the possibility to calculate the paths of his robots as far as it is possible. The prerequisite for this is the precise measurement of work pieces and tools with LaserLAB.

In addition, the entire production line is protected against downtime by re-teaching. If the line is moved later, not a single robot has to be reteached.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

Cell description

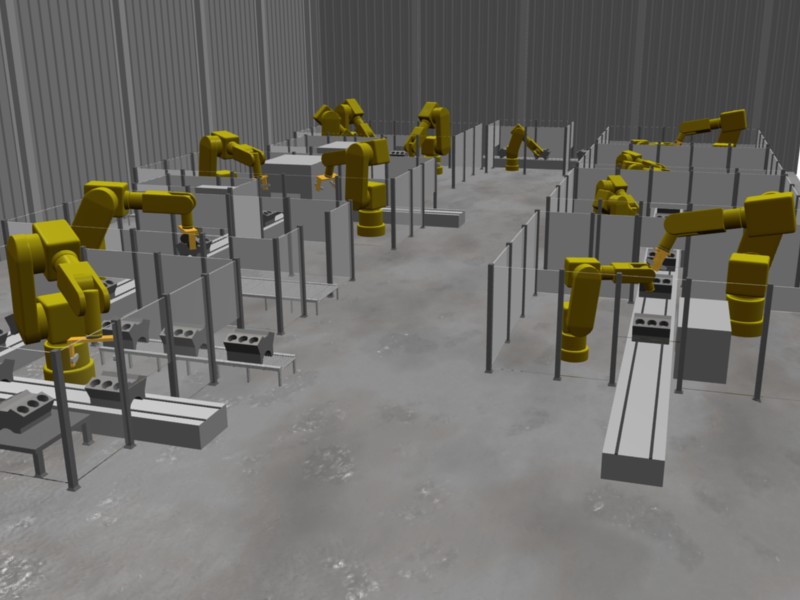

The customer is setting up an engine assembly line for a car manufacturer. A total of 26 high-precision ABB IRB 4400 and IRB 6640 robots are used, distributed over 15 stations and performing different tasks. These range from handling tasks to the application of adhesives or sealants, assembly and leak testing.

Task

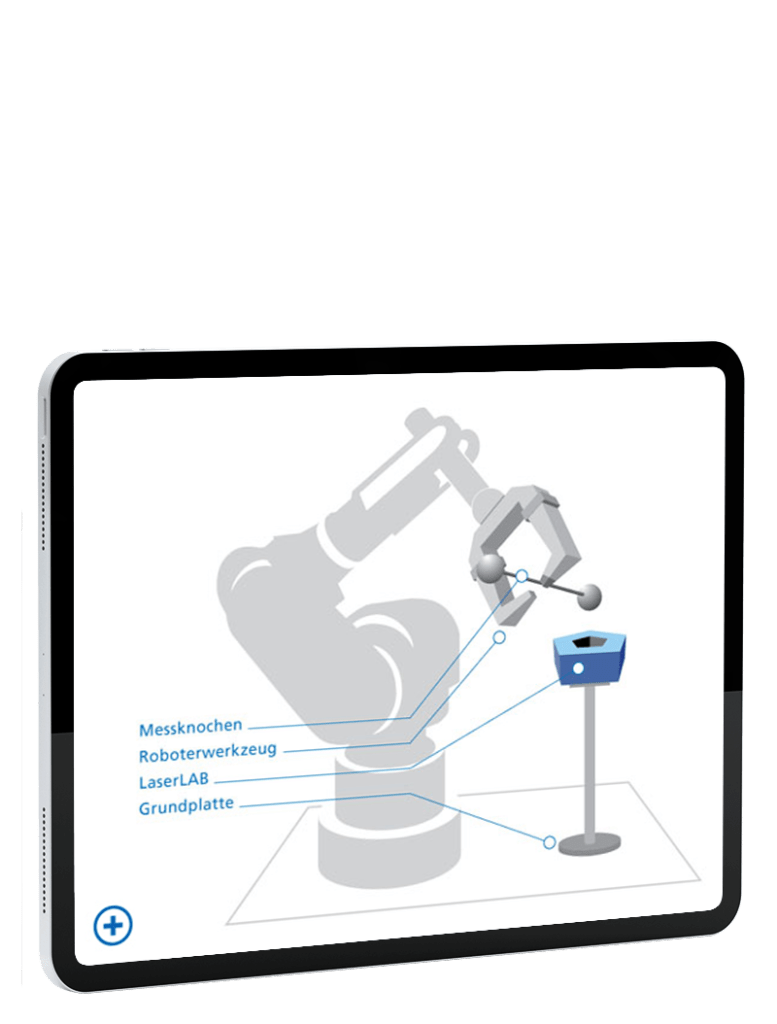

The end customer wants the robot programmes to contain as few points as possible. Ideally, programmes should have a single starting point from which all other points are calculated. To enable this calculation, the work objects and tools must be defined as accurately as possible.

In addition, the plant must be protected against possible production stoppages.

Implementation

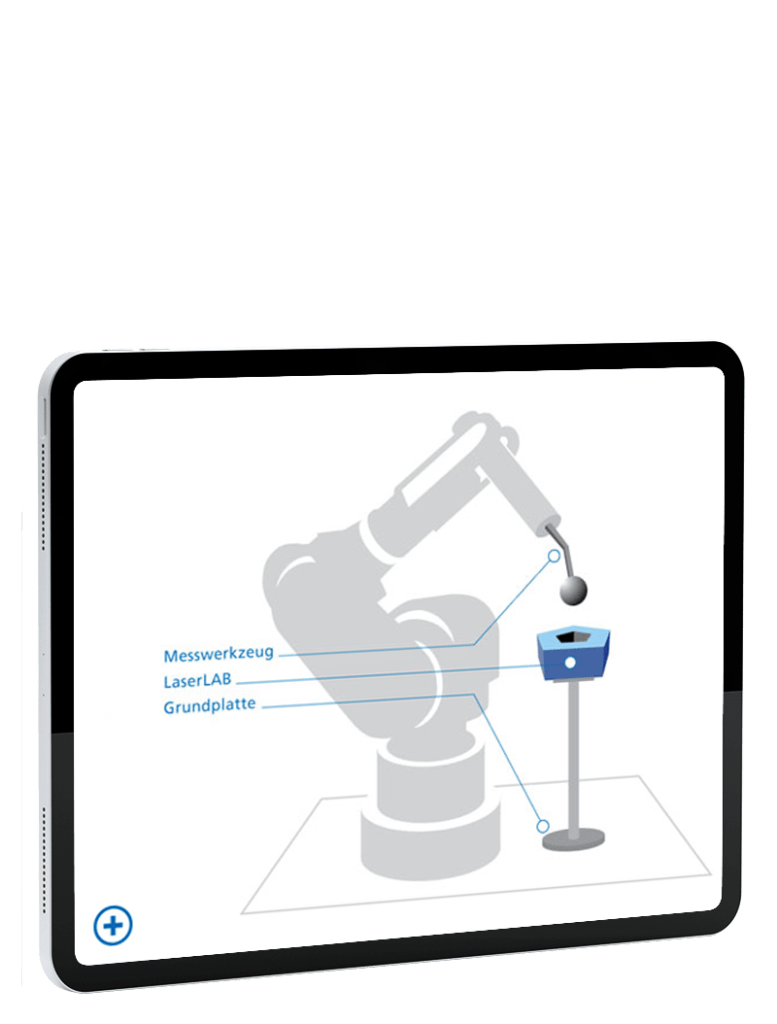

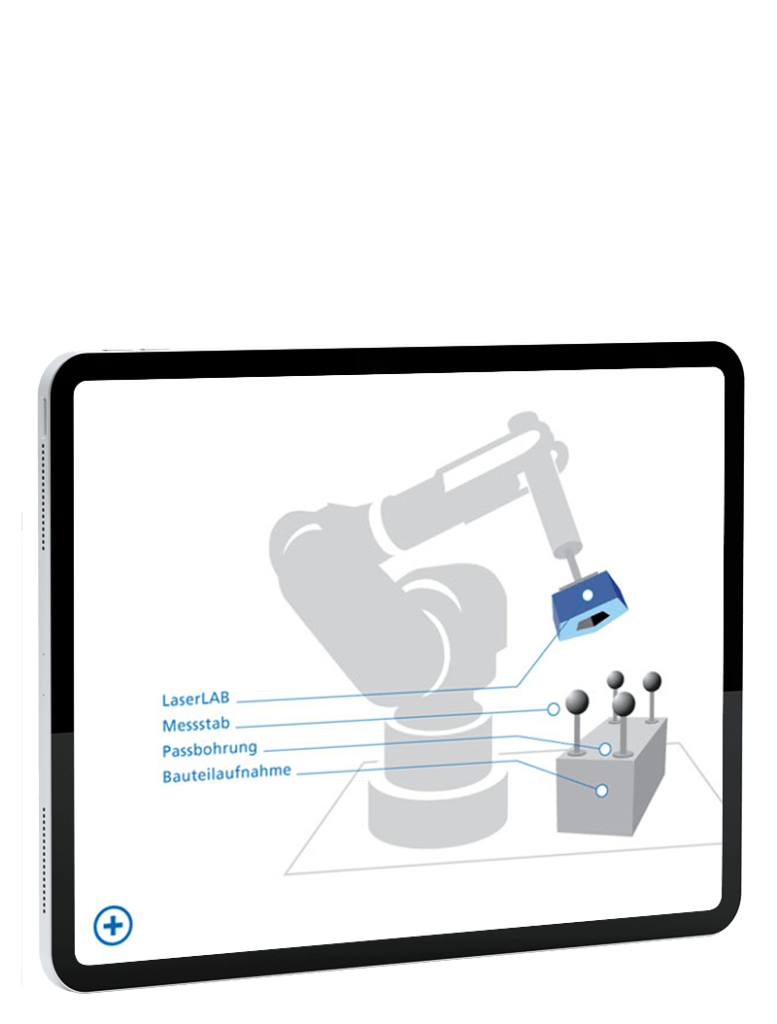

Using Wiest technology, the hardware of each station on the production line is digitally stored. This makes it possible to immediately restore the reference between the hardware and the robot programmes in the event of a crash or after replacing parts on the robot or tool.

Products

These Wiest products were used:

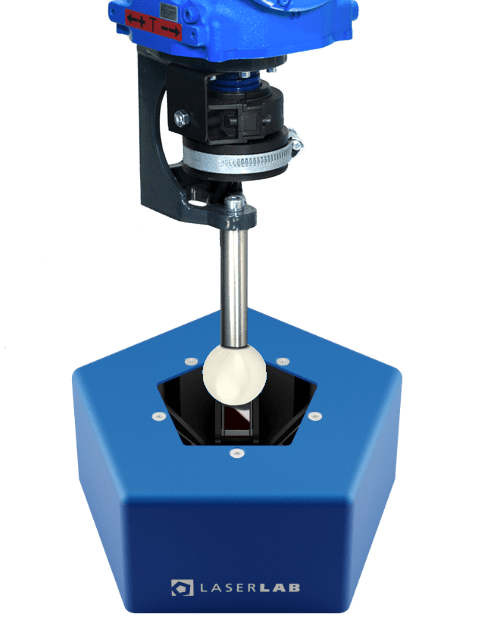

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Wenden Sie sich an unser Support-Team bei allen technischen Fragen

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Safeguarding of complex machining cells

Safeguarding of complex machining cells Two absolute-precision