Your specialist in intelligent calibration of industrial robots!

Automatically eliminate mechanical tool deviations and robot alignment errors after collisions.

WIEST CALIBRATION SYSTEMS - THE ADVANTAGES

Ensure maximum performance in robotic production - technically and economically.

The perfect calibration solution for any application

Easy integration - fast commissioning

High-precision calibration - without programming knowledge

Highest process reliability - through fully automated tool measurement

Expert support - at every stage of production

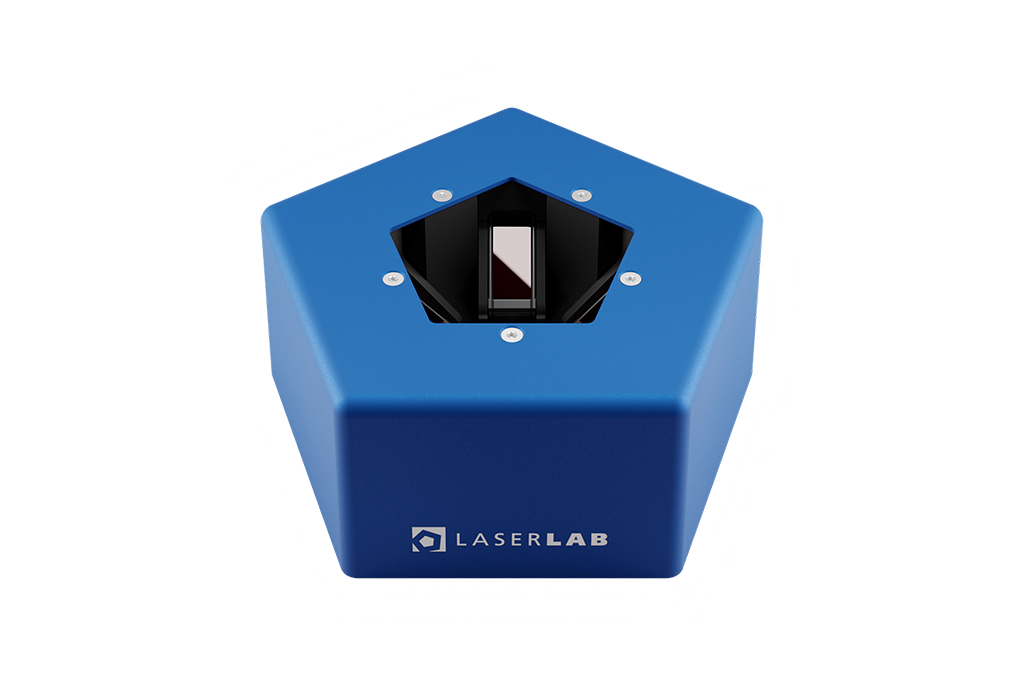

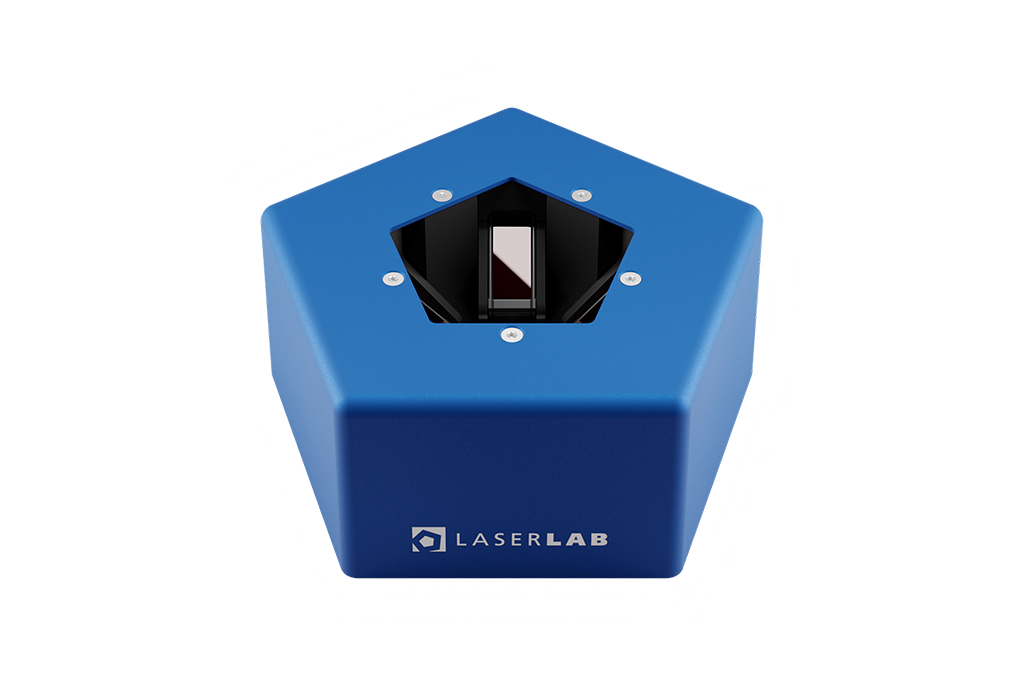

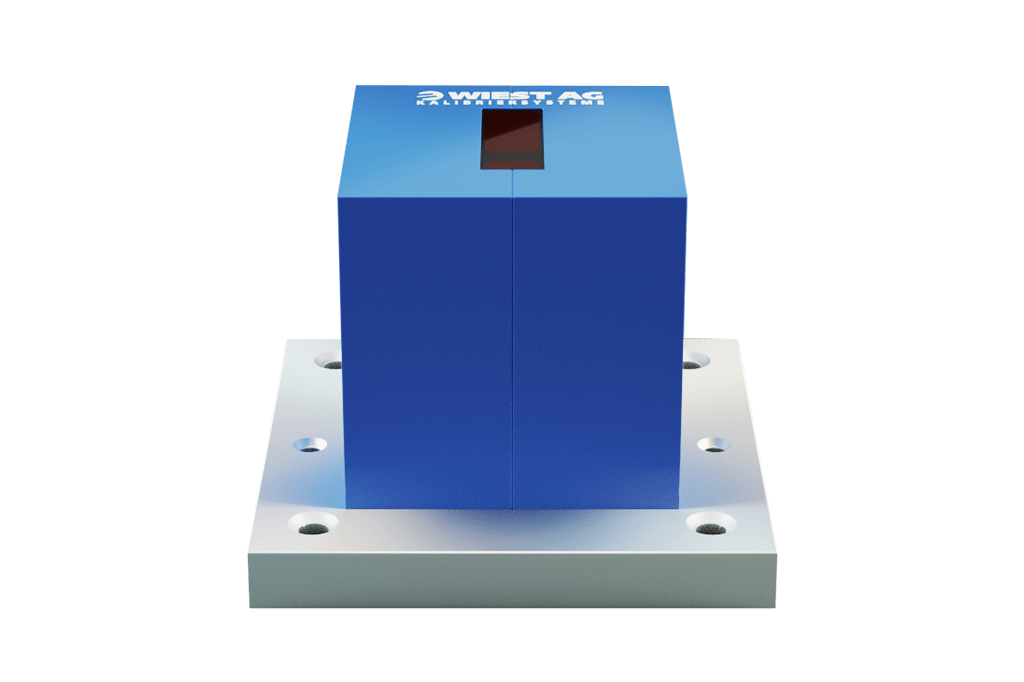

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration - LaserLAB

Portable, compact and unrivalled in its versatility. Tightly integrated with the software modules of the Wiest:In Calibration Manager, LaserLAB is an incomparably powerful tool. For almost any kinematic measurement and calibration task during commissioning, operation and maintenance of complex robotic cells.

Robot calibration, tool measurement, measurement of user coordinate systems and additional axes. With LaserLAB, you have a centralised measurement system that takes care of all the measurement tasks directly in the production cell.

Integrated into the robot controller, all processes, including error correction, are fully automated if required. For minimised downtime, assured process quality and maximum productivity.

- One system for all your measurement and calibration needs

- Enables fully automated calibration of robots in the manufacturing cell

- Compatible with almost all common types of industrial robots

- Minimises plant downtime

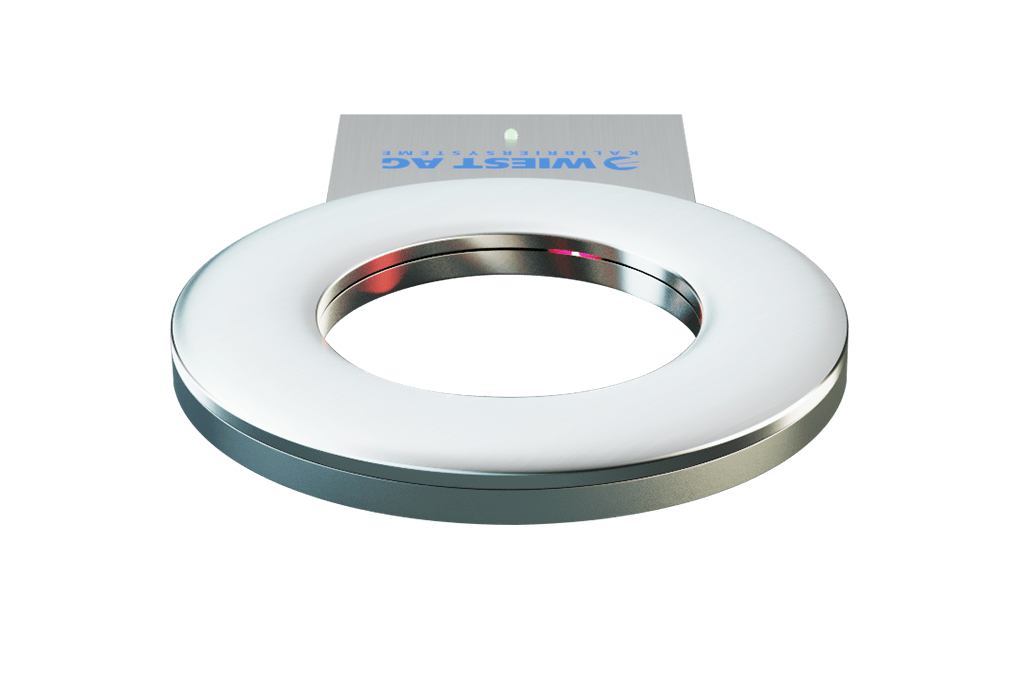

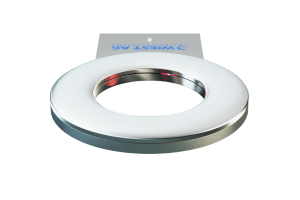

RotoLAB | 360° TCP Measurement of Rotationally Symmetric Tools

Calibrates tools such as welding and glue guns in seconds - RotoLAB

With RotoLAB, time-consuming re-teaching is a thing of the past. 4 seconds – and the robot controller knows whether the current tool center point (TCP) is within the tolerance range. In the event of a deviation, a full tool measurement is carried out automatically in 30 seconds and the corrected tool coordinates are sent directly to the control.<

Equipped with a 360° sensor, RotoLAB is specifically designed for maximum efficiency in the inspection and calibration of rotationally symmetric robotic tools.

- Fully automatic 360° XYZ TCP correction in < 30 seconds

- Handles cyclic, process-controlled measurements and operator requests

- Automatic TCP measurement during tool change

- Freely configurable thresholds and parameters for operator authorisation

- Rapid return on investment through the effective minimisation of defective parts and downtime

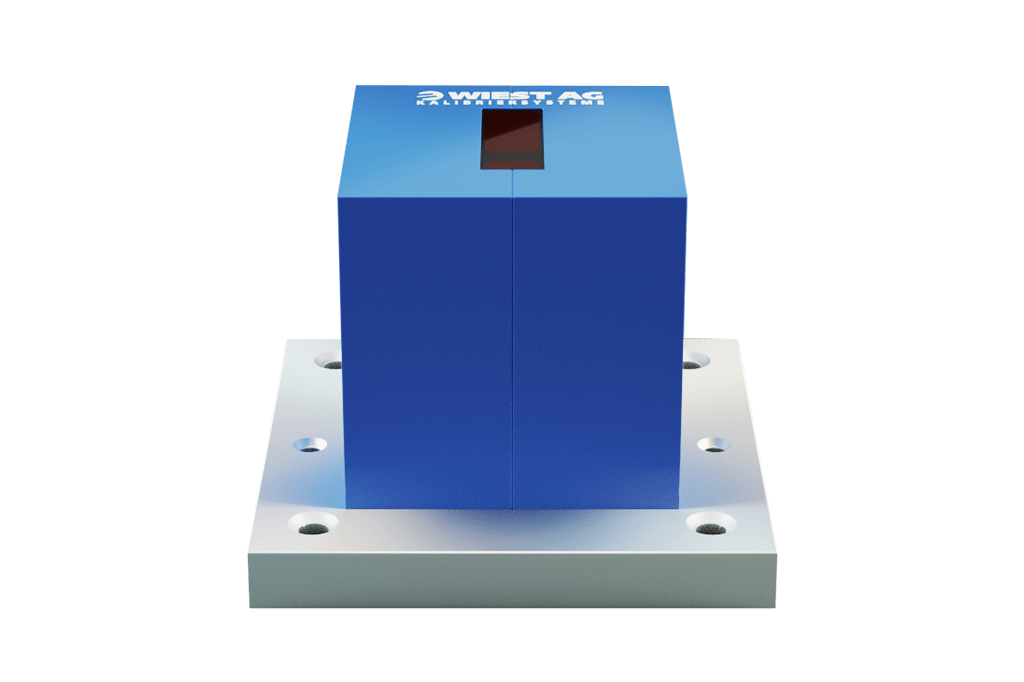

GripLAB | High-precision calibration system for 6D gripper or toolframe measurement

Maximum process reliability in the interaction between gripper and components - GripLAB, 6D calibration

GripLAB provides complete 6D measurement of a gripper or component including orientation in <60 seconds. The system can take control measurements during operation, detect any positional deviation and correct it automatically.

The system captures the entire possible error chain from the robot flange to the component in one step, thereby increasing the process reliability and availability of handling cells. Even after collisions, the cells can be brought back into operation in the shortest possible time.

- Complete 6D measurement of a gripper/part in less than 60 seconds

- Software-driven commissioning in minutes after installation

- Automatic transfer of the correction values

- Allows gripper measurement without the need for probes or other tools

- Data communication via serial, Ethernet or optional fieldbus

- Fast, effective restoration of web accuracy across all stations

- Calibration accuracy < 0.2 mm

Wiest Software Solutions

We have the right LaserLAB modules for every size and application

The LaserLAB software is the link between the measurement system and the robot controller, ensuring automatic data exchange, allowing individual configurations, determining the optimum results for each measurement task from the individual measurement data, visualising the results and logging them, thus increasing the user-friendliness of cell calibration.

- Uniform user interface for all controllers

- Safeguarding the robot alignment

- Robot calibration

- Absolute measurement

- Tool measurement in 3D-6D

- User frame / Base / Workobject / Frame measurement

- Easy to install

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration - LaserLAB

Convenient, compact and unrivalled in its versatility. Tightly integrated with the software modules of the Wiest:In Calibration Manager, LaserLAB is an incomparably powerful tool. For almost any kinematic measurement and calibration task during commissioning, operation and maintenance of complex robot cells.

- One system for all your measurement and calibration needs

- Enables fully automated calibration of robots in the manufacturing cell

- Compatible with almost all common types of industrial robots

- Minimises plant downtime

RotoLAB | 360° TCP measurement of rotationally symmetrical tools

Calibrates tools such as welding hands and glue guns in seconds - RotoLAB

With RotoLAB, time-consuming re-teaching is a thing of the past. 4 seconds – and the robot controller knows whether the current tool center point (TCP) is within the tolerance range. In the event of a deviation, a full tool measurement is carried out automatically in 30 seconds and the corrected tool coordinates are sent directly to the control.<

Equipped with a 360° sensor, RotoLAB is specifically designed for maximum efficiency in the inspection and calibration of rotationally symmetric robotic tools.

- Fully automatic 360° XYZ TCP correction in < 30 seconds

- Handles cyclic, process-controlled measurements and operator requests

- Automatic TCP measurement during tool change

- Freely configurable thresholds and parameters for operator authorisation

- Rapid return on investment through the effective minimisation of defective parts and downtime

GRIPLAB | HIGH-PRECISION CALIBRATION SYSTEM FOR 6D GRIPPER OR TOOLFRAME MEASUREMENT

Maximum process reliability in the interaction between gripper and components - GripLAB, 6D calibration

GripLAB provides complete 6D measurement of a gripper or component including orientation in <60 seconds. The system can take control measurements during operation, detect any positional deviation and correct it automatically.

The system captures the entire possible error chain from the robot flange to the component in one step, thereby increasing the process reliability and availability of handling cells. Even after collisions, the cells can be brought back into operation in the shortest possible time.

- Complete 6D measurement of a gripper/part in less than 60 seconds

- Software-driven commissioning in minutes after installation

- Automatic transfer of the correction values

- Allows gripper measurement without the need for probes or other tools

- Data communication via serial, Ethernet or optional fieldbus

- Fast, effective restoration of web accuracy across all stations

- Calibration accuracy < 0.2 mm

Wiest Software Solutions

The right module for every requirement

The Wiest software allows you to integrate the calibration solutions into your robot cell in a user-friendly way

- Easy to use

- Robot calibration

- Absolute measurement

- Tool measurement in 3D-6D

WIEST Calibration Systems - Best Practice Applications

Application examples from the field: Robot programming made easy and efficient with Wiest measurement and calibration systems

Services

Wiest offers customer support throughout the entire lifecycle. For highest efficiency from planning, to sustainable technical support

We can help you find the causes, advise on possible solutions and offer complete solutions with customised measurement programmes and systems. Contact us.

Our experienced team of robotics specialists will work hand in hand with you to efficiently implement cell calibration solutions and train your staff to use the systems.

Complete measurement data logs allow optimal remote support by our experts. Our support is also available for spontaneous problems via e-mail, telephone, video call or on-site.

You have any questions? Our experts will be happy to assist you.

Just fill in the form or call us directly.

References

Companies that trust us

Optimisation of cell kinematics accuracy or restoration after mechanical deviations;

Wiest AG is represented in all industries where industrial robots are at home.