Difficult to access machine loading

When moving a highly complex, out-of-sight cell, it is essential to avoid a lengthy production stoppage.

Wiest advantages

Customer benefits

The deviations that occurred were corrected by the Wiest software, and the line was immediately returned to production. Wiest AG helped the customer reduce a lengthy production stoppage to a minimum.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

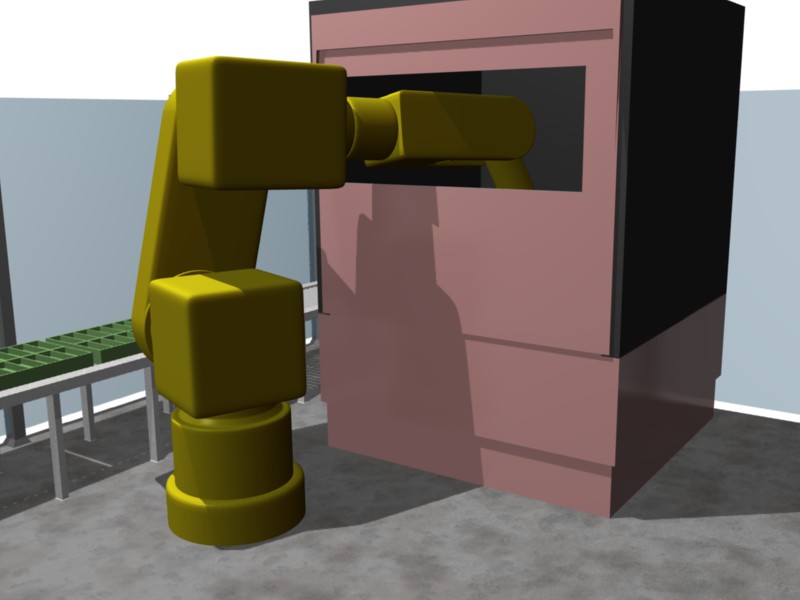

Cell description

The plant produces shift forks for transmissions. A KUKA KR30 feeds the parts into an out-of-sight CNC milling machine. There they are inserted into the machine by the robot. This process is highly complex and is supported by a force-torque sensor that guides the robot.

Task

The cell is to be moved. The existing robot programmes are very difficult to teach because the cell is not observable. Teaching itself is only possible with mirrors. This line is also important for the customer’s global production. A lengthy production stoppage for a time-consuming teach-in would therefore be unacceptable.

Implementation

Products

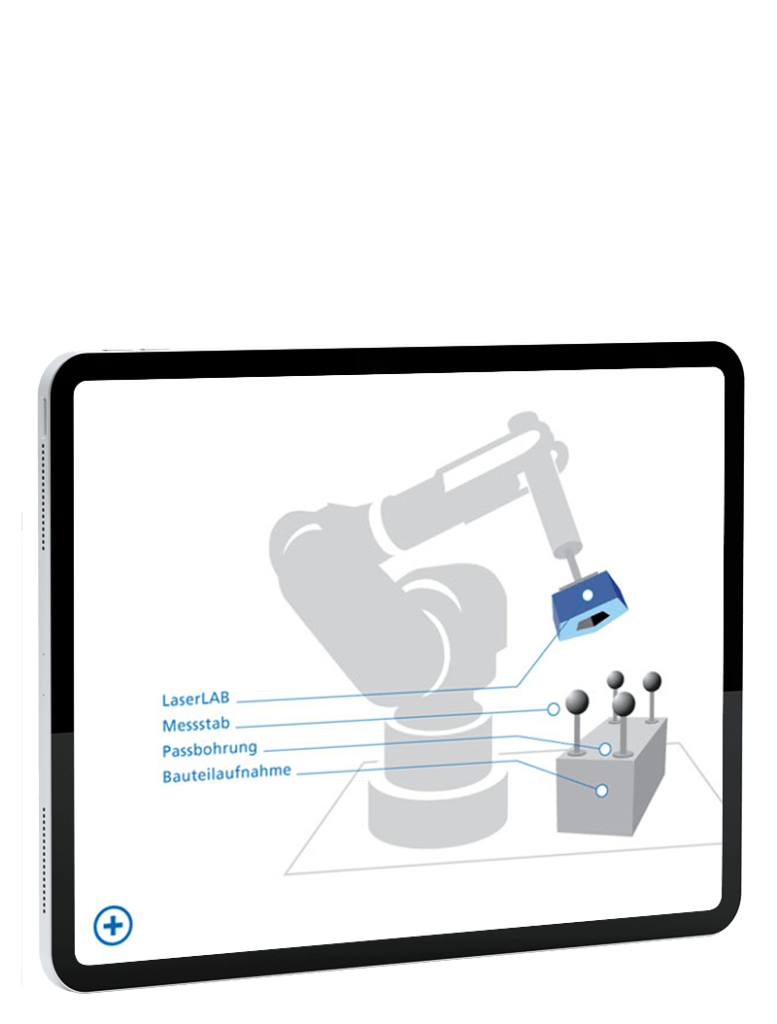

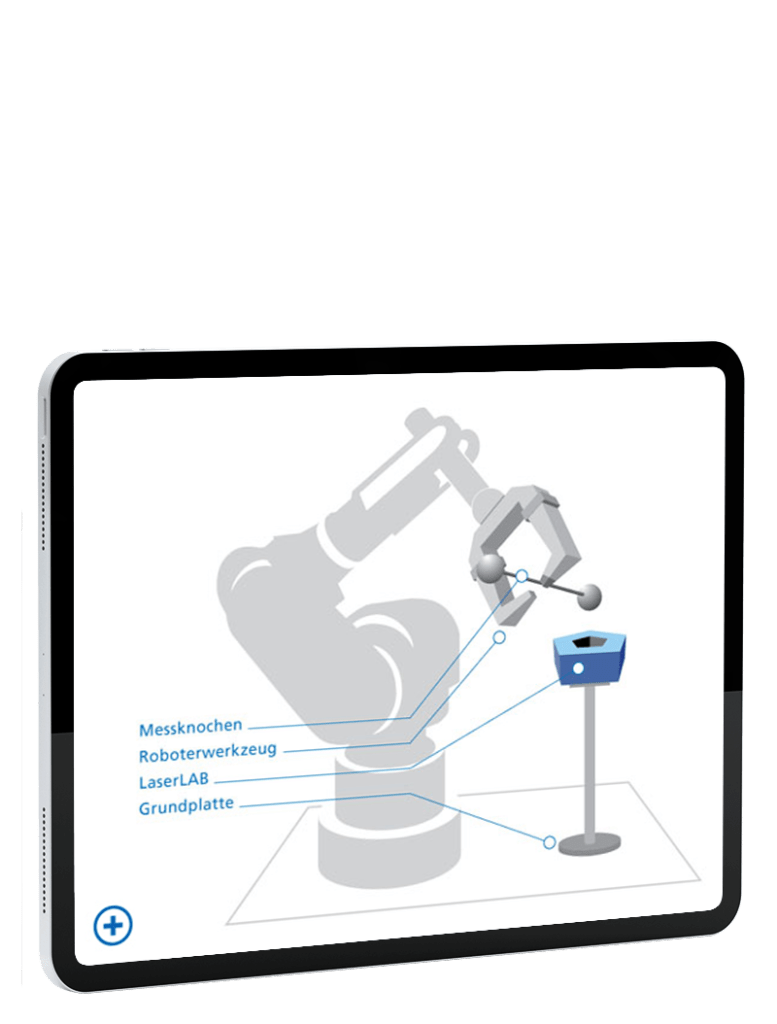

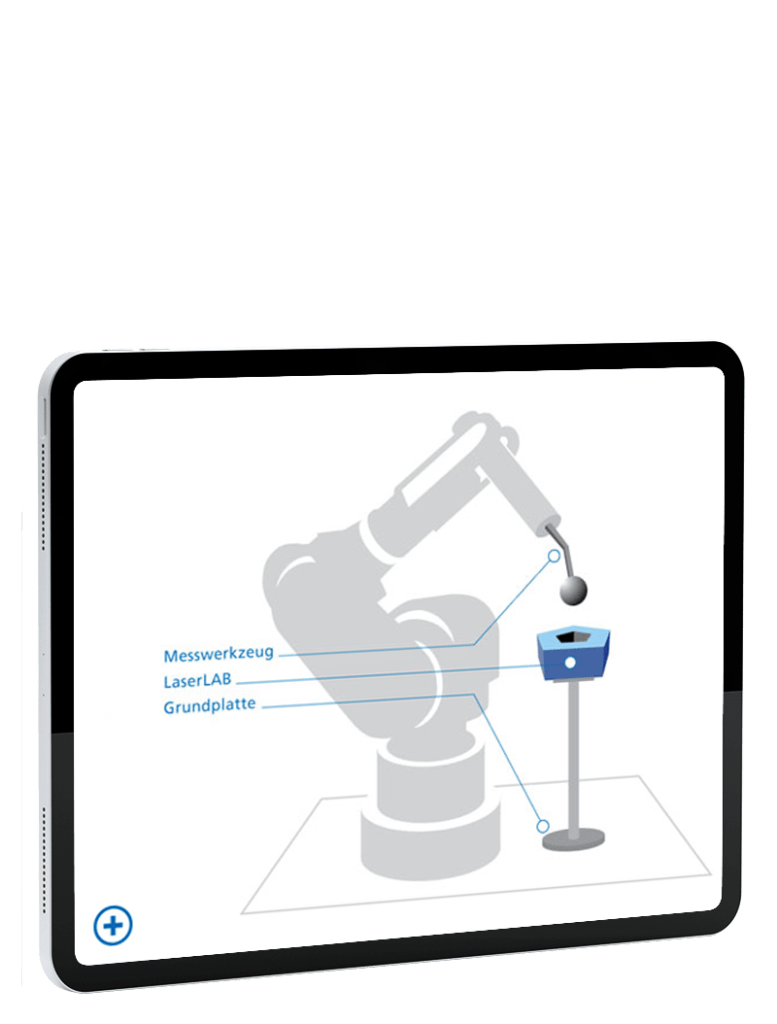

These Wiest products were used:

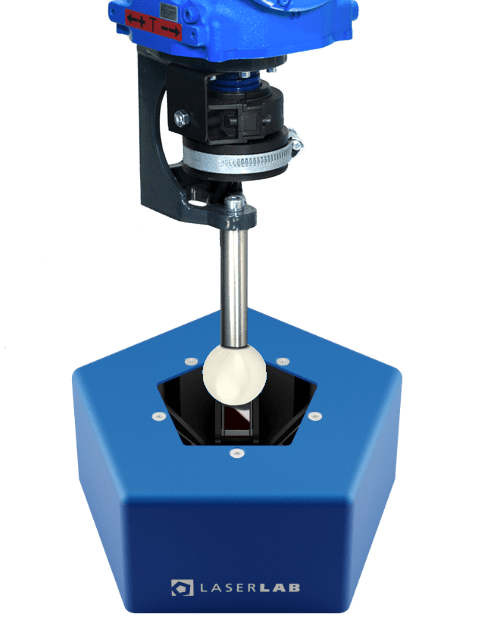

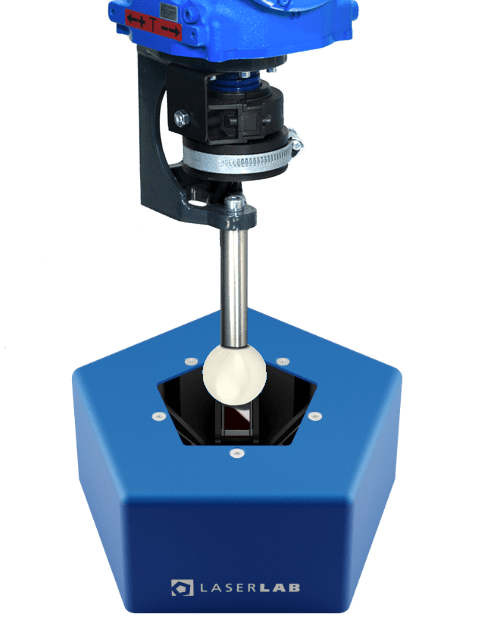

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order

Products

These Wiest products were used: