Robot cell for quality inspection

When building robotic systems for materials testing, a constant sequence of robot programmes with constant sensor spacing must be ensured.

WIEST advantages

Customer benefits

By using LaserLAB, the customer is able to maintain its robot systems, which are sold worldwide, according to a standardised method.

Integration on the second line without reteaching

Increase availability

Downtime avoidance

Shortening the commissioning

Case

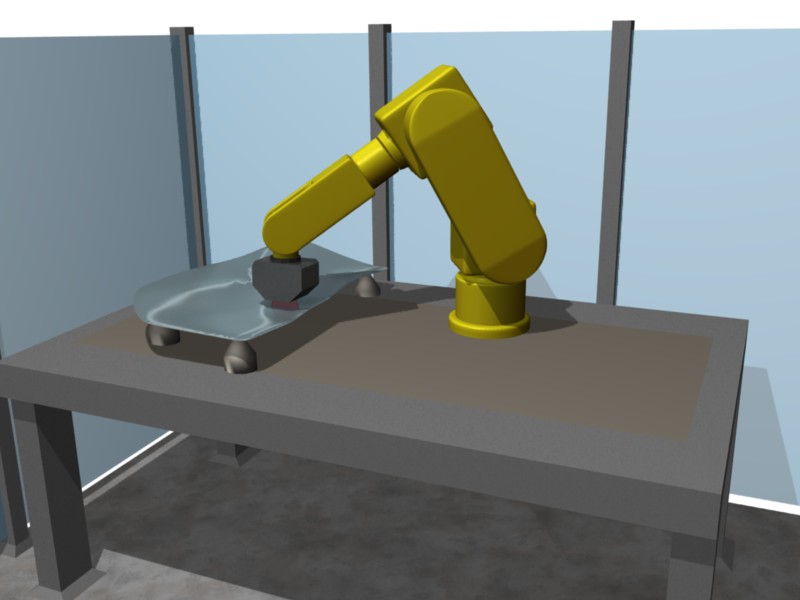

Cell description

The customer builds robot systems for material testing of machine elements. A sensor is guided over the material surface by a Mistubishi RV-6SL. The residual stresses of the component are measured and any grinding burn or heat treatment defects are detected.

Task

In order to perform the measurement task correctly, it is important that the distance between the sensor and the surface of the material to be tested remains the same. Failure to do so will result in incorrect readings.

For reliable measurement results, it is important to ensure that the robot programmes always run in the same way. It is therefore very important for the customer that the robot always has the same mastering.

As the robots are not pinned but screwed onto a standard profile, the geometric relationship between the robot and the specimen is also critical.

Implementation

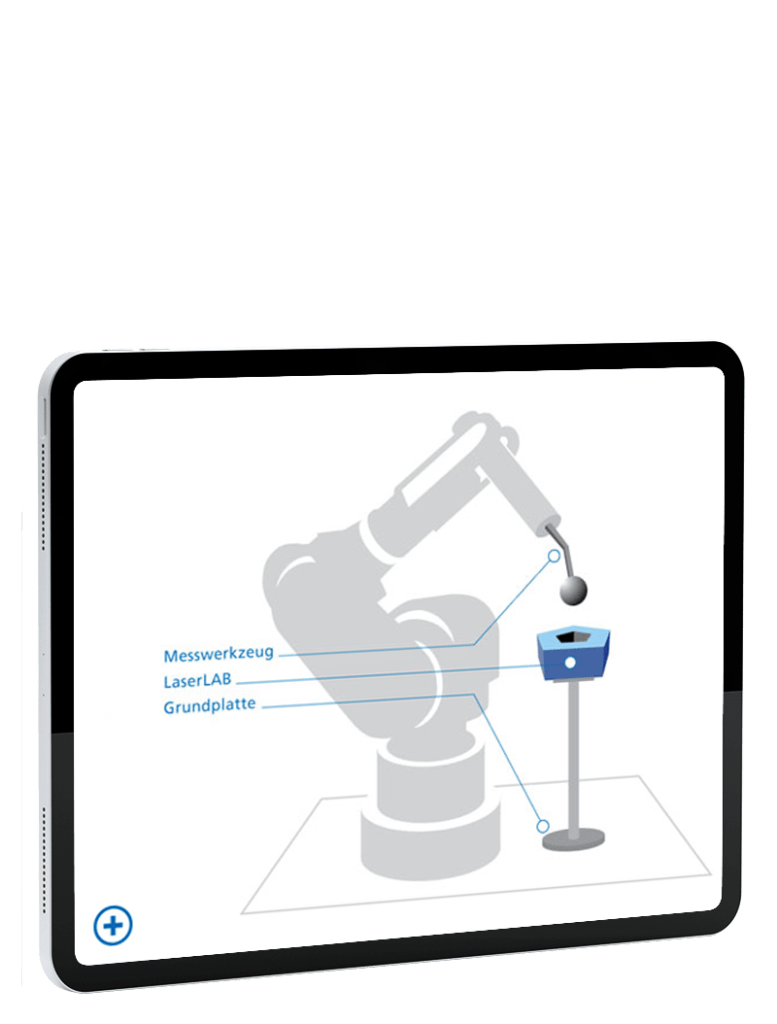

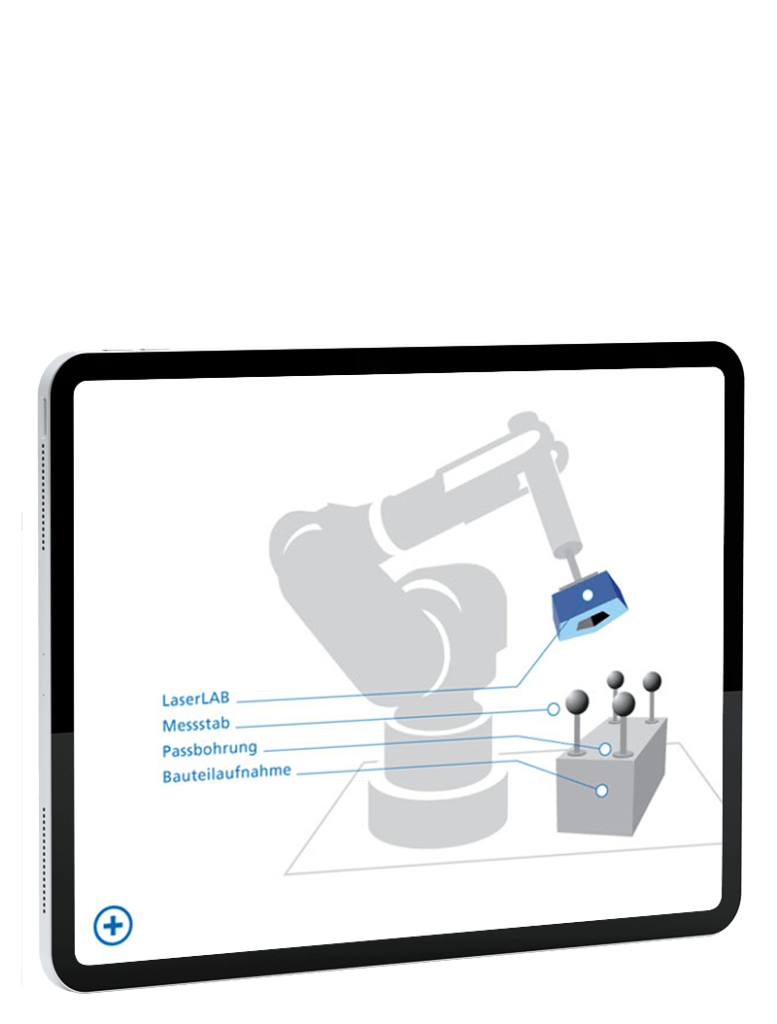

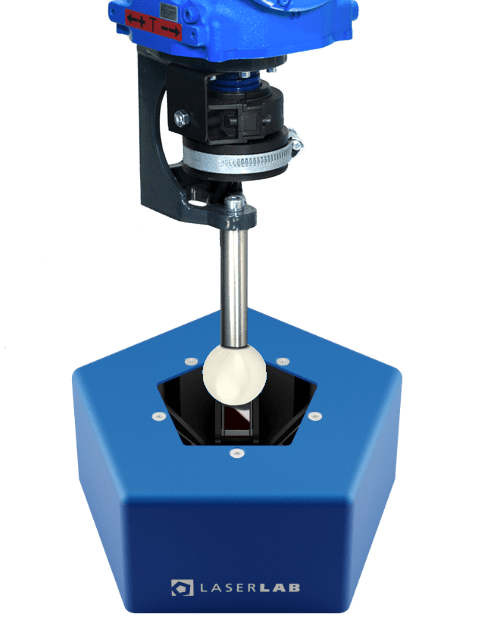

An adapter with two mechanical connections was mounted on the flange of the Mitsubishi, one for a measuring rod and the other to hold the LaserLAB.

A base plate for screwing on the LaserLAB is permanently attached to the machine frame.

Both loop:in for robot calibration and base:in for workpiece fixture calibration were performed.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Wenden Sie sich an unser Support-Team bei allen technischen Fragen

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order