Does your robot's gluing or welding path deviate from the nominal path? RotoLAB calibrates your tool!

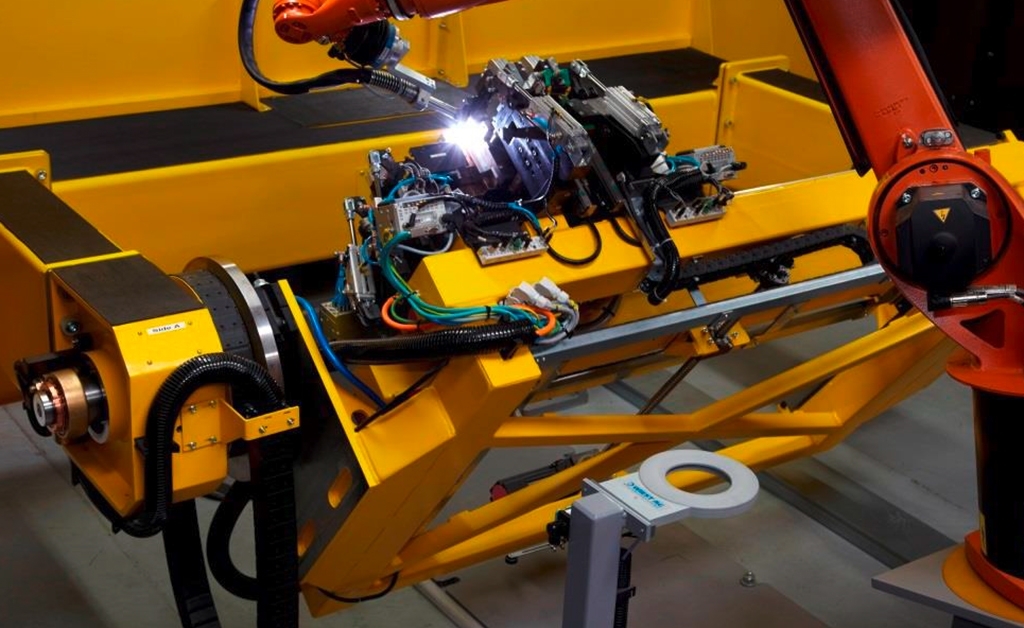

Our RotoLAB measurement system allows you to quickly and fully automatically check and recalibrate your robot tools using 3D measurement.

RotoLAB benefits

360° TCP measurement of rotationally symmetric tools

Fully automatic 360 degree X-Y-Z tool centre point correction in less than 30 seconds

Cyclic measurement process controlled and/or on operator request

Automatic TCP measurement during tool change

Freely configurable operator enable limits and parameters

Rapid payback through effective minimisation of defective parts and downtime

ROTOLAB | 360° TCP measurement of rotationally symmetric tools

Calibrates tools such as welding and glue guns in seconds - RotoLAB

With RotoLAB, time-consuming re-teaching is a thing of the past. 4 seconds – and the robot controller knows whether the current tool center point (TCP) is within the tolerance range. In the event of a deviation, a full tool measurement is carried out automatically in 30 seconds and the corrected tool coordinates are sent directly to the control.<

Equipped with a 360° sensor, RotoLAB is specifically designed for maximum efficiency in testing and calibrating rotationally symmetric robotic tools.

- Welding torches

- Soldering tools

- Adhesive nozzles

- Plasma cutter

- Torches

- Spot-welding guns

- Workpieces for joining applications

Process

How the calibration process works with RotoLAB

The short test duration of four seconds allows continuous monitoring of the welding torch. If a threshold is exceeded during a test, calibration is automatically initiated. In the case of minor deviations in the tool data, the changes are automatically transmitted to the robot; in the case of major deviations, the robot stops and the operator must manually confirm the update of the tool data.

See the calibration process in action in the adjacent video.

The individual process steps

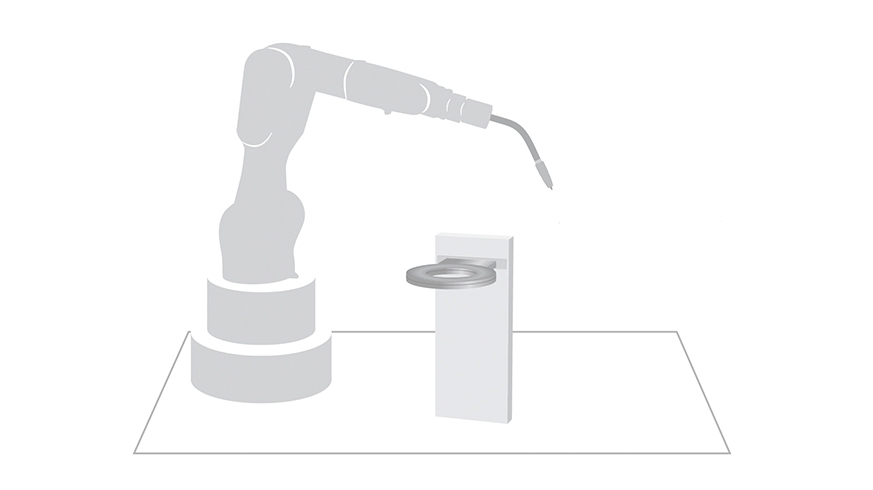

Initial situation

Die Inbetriebnahme kann in wenigen Minuten durchgeführt werden, ohne dass die aktuellen Werkzeugdaten in der Robotersteuerung geändert werden müssen.

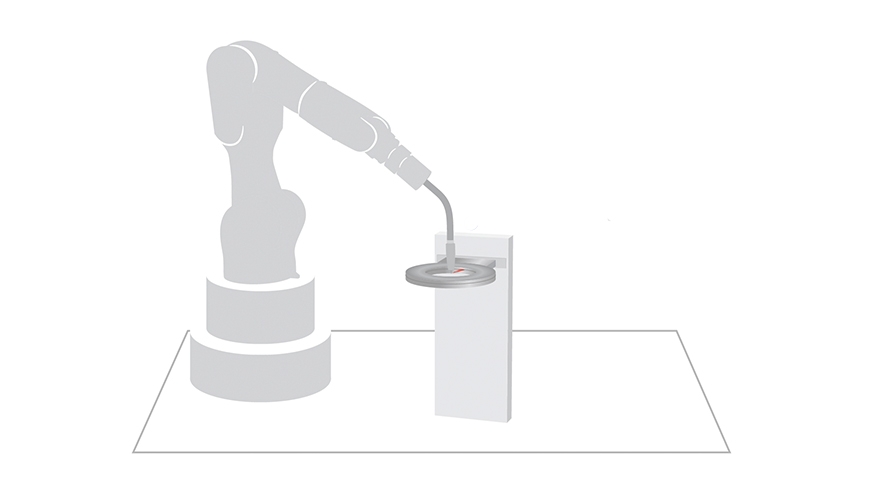

Check

The robot moves cyclically with the torch into the RotoLAB. The test is performed using an XYZ measurement. If the torch is centred, the TCP is within the tolerance range.

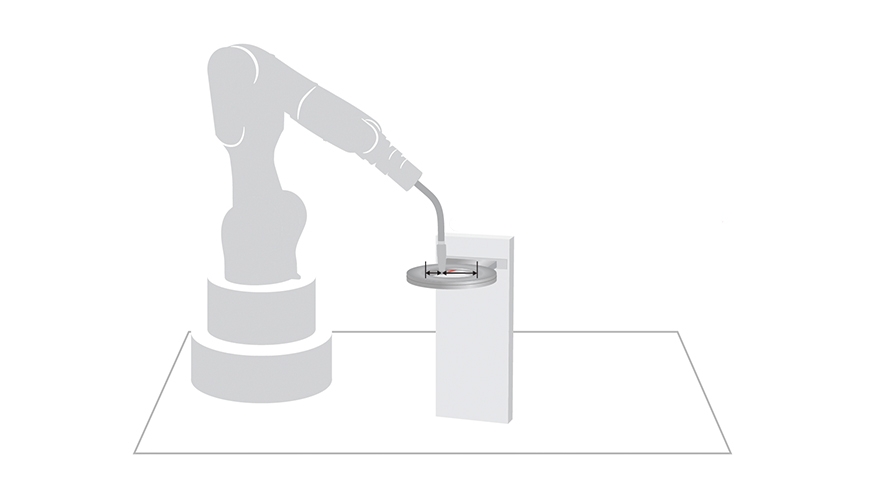

Calibration

If the check shows that the torch is not centred, a new XYZ measurement is made. The new tool data is transferred to the control.

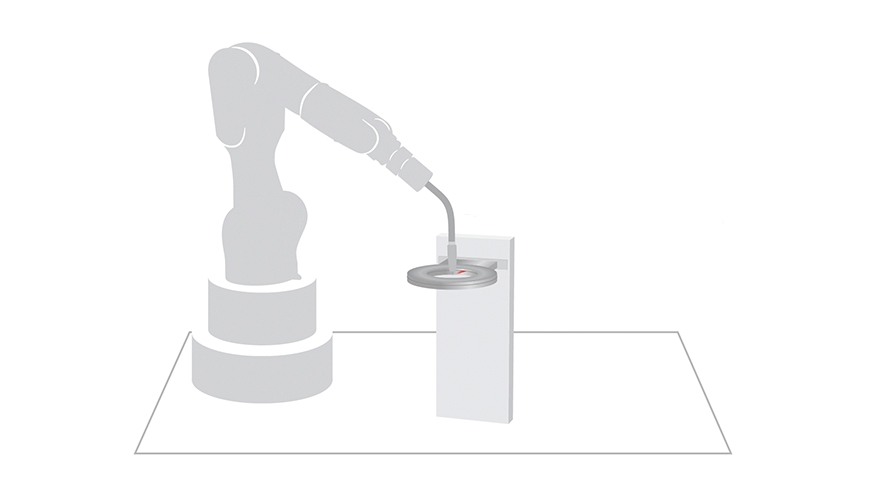

Control measurement

The burner is centred again. The TCP (tool center point) is checked again.

Price configurator

Here you can pre-configure your individual RotoLAB including price for your product.

At the end of the enquiry you will be given the option to contact us directly or arrange a callback.

Software

Fully integrated into your controller

RotoLAB fully integrated into the robot controller

The RotoLAB system is configured and parameterised directly from your robot’s HMI.

You can integrate tool measurement to your tolerances fully automatically into your production process, or trigger it manually during maintenance work on the robot or tool.

Hardware

RotoLAB is available in two versions

RotoLAB

Interface: 1x RS232

Multi-Robot Support: No

Supports:

- ABB

- FANUC

- KUKA KRC2

RotoLAB IP

Interface: M12 Ethernet

Multi-Robot Support: Yes (up to 4)

Supports:

- ABB

- FANUC

- KUKA KRC4

Production equipment, Tier One

"The short measurement time allows us to check the torch after each welded part. This maximises our process reliability without losing cycle time."

Production equipment, TIER ONE

"The short measurement time allows us to check the torch after each welded part. This maximises our process reliability without losing cycle time."

Compatible robot systems

RotoLAB is compatible with:

RotoLAB is controlled directly via the robot programme. The robot programmes are included in the scope of delivery. Set-up and configuration or parameterization is done directly via robot HMI

Interested in RotoLAB? We will be happy to advise you.

Just fill in the form or call us directly.

FAQ

Häufig gestellte Fragen zu RotoLAB

- Does the tool need to be replaced with a test probe for calibration?No. Direct measurement of the current tool is usually used. No special measuring tools are required. With some welding torches it may be necessary to remove the gas nozzle to make the measurement.

- What kind of Tools can be calibrated using RotoLAB?RotoLAB can calibrate all rotation-symetric tools.

- What types of connection are available for the RotoLAB?The RotoLAB system is available as a serial or Ethernet device. The serial system can be integrated with all common fieldbus systems via protocol converters. The Ethernet version and the fieldbus integration also have the advantage that up to 4 robots can share one system (provided they are accessible).

Services

Our customer support team is here to help you. Please do not hesitate to contact us.

We can help you find the causes, advise on possible solutions and offer complete solutions with customised measurement programmes and systems. Contact us.

Our experienced team of robotics specialists will work hand in hand with you to efficiently implement cell calibration solutions and train your staff to use the systems.

Complete measurement data logs allow optimal remote support by our experts. Our support is also available for spontaneous problems via e-mail, telephone, video call or on-site.