Solutions for all your measurement tasks around industrial robots

Find out more about our all-in-one solution LaserLAB as well as our measurement sensor technology for welding torches, plasma torches or spot welding guns, RotoLAB or about our latest system GripLAB for automatic TCP control and calibration of robot grippers.

We offer customized solutions to all measurement and calibration requirements for industrial robots. WIEST AG products accompany you through your entire production process, from commissioning of the robot cell to production and maintenance.

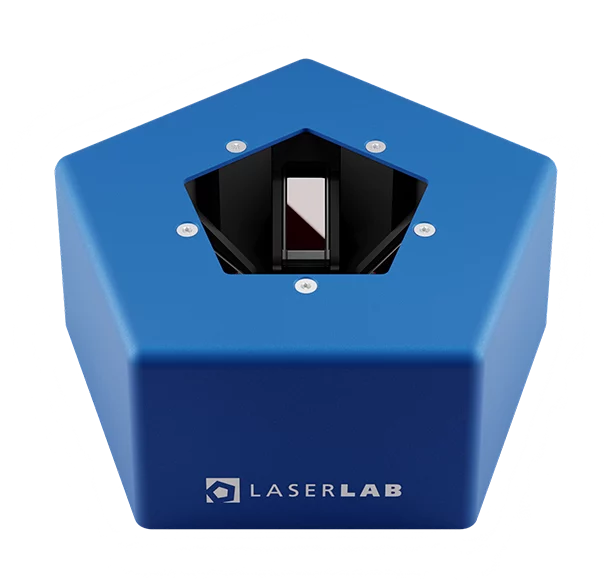

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration - LaserLAB

Convenient, compact and unrivalled in its versatility. Tightly integrated with the software modules of the Wiest:In Calibration Manager, LaserLAB is an incomparably powerful tool. For almost any kinematic measurement and calibration task during commissioning, operation and maintenance of complex robot cells.

Whether robot calibration, tool measurement, measurement of user coordinate systems and additional axes. With LaserLAB, you have a centralised measurement system that takes care of all the measurement tasks directly in the production cell.

Integrated into the robot controller, all processes, including error correction, are fully automated if required. For minimized downtimes, assured process quality and maximum productivity.

- One system for all measurement and calibration tasks

- Enables fully automated robot calibration in the manufacturing cell

- Compatible with almost all common types of industrial robots

- Minimises plant downtime

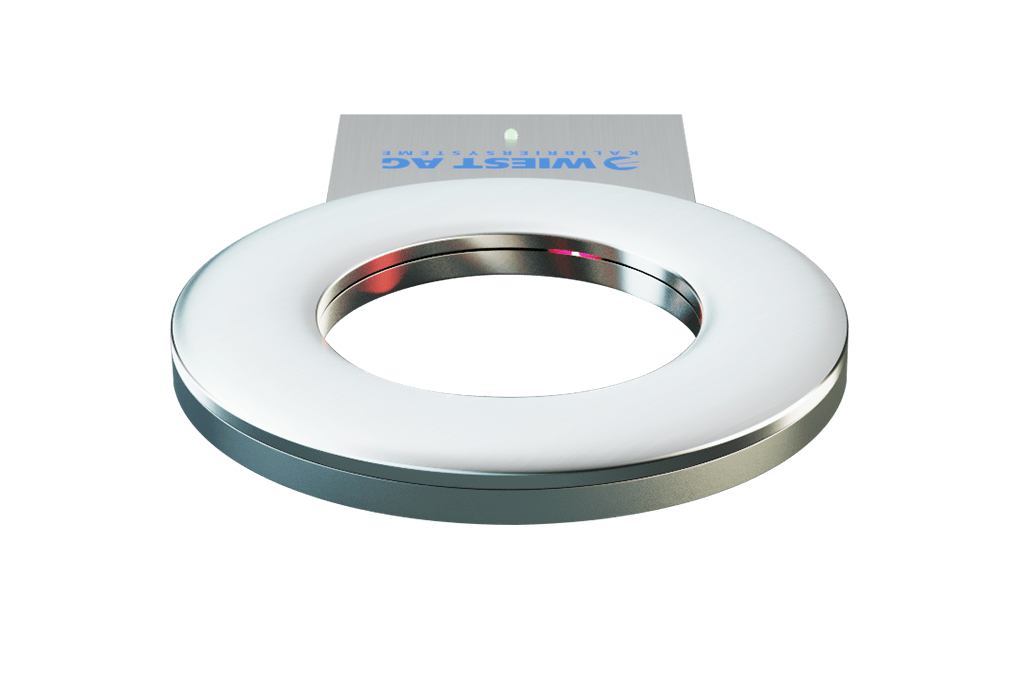

RotoLAB | 360° TCP Measurement of Rotationally Symmetric Tools

Calibrates tools such as welding and glue guns in seconds - RotoLAB

- Fully automatic 360° XYZ TCP correction in < 30 seconds

- Handles cyclic, process-controlled measurements and operator requests

- Automatic TCP measurement during tool change

- Freely configurable thresholds and parameters for operator authorisation

- Rapid return on investment through the effective minimisation of defective parts and downtime

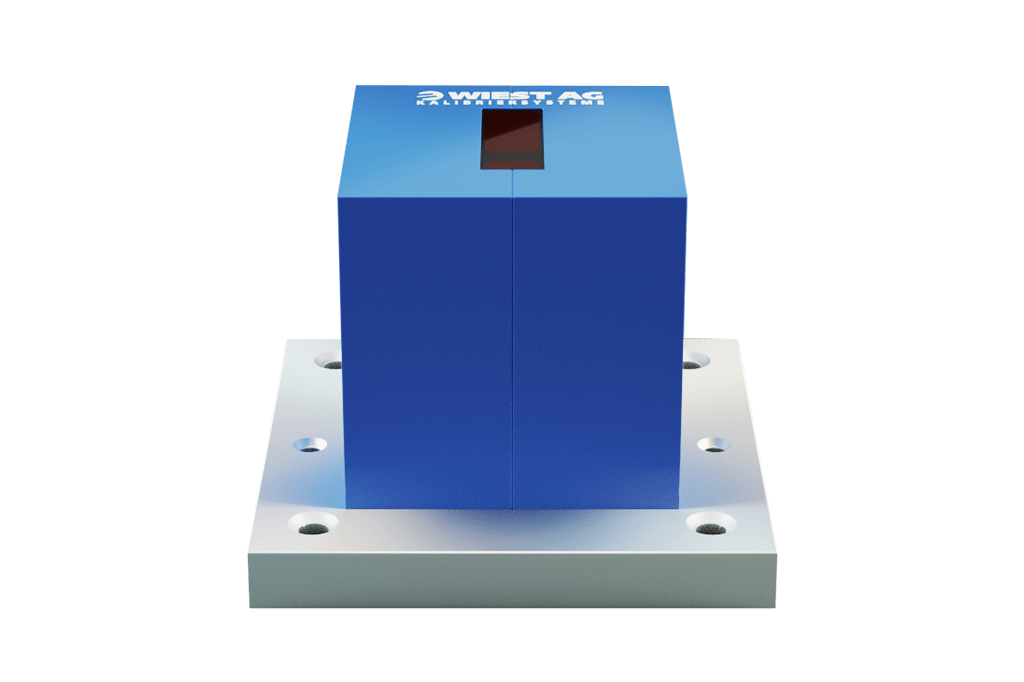

GripLAB | High-precision calibration system for 6D gripper or toolframe measurement

Maximum process reliability in the interaction between gripper and components - GripLAB, 6D calibration

GripLAB enables complete 6D measurement of a gripper or component, including orientation, in less than 60 seconds.< The system can take control measurements during operation, detect any positional deviation and correct it automatically.

The system captures the entire possible error chain from robot flange to component in one step, improving process reliability and cell availability. This means that even after a collision, you can get the cells back up and running in no time.

- Complete 6D measurement of a gripper/part in less than 60 seconds

- Software-driven commissioning in minutes after installation

- Automatic transfer of the correction values

- Allows gripper measurement without the need for probes or other tools

- Data communication either via Profinet, Profibus, Ethernet or

- Fast, effective restoration of web accuracy across all stations

- Calibration accuracy < 0.2 mm

Wiest Software Solutions

The right software for every situation.

The Wiest software allows you to integrate the calibration solutions into your robot cell in a user-friendly way.

- Automatic loading of machine kinematics

- Fully automatic data acquisition based on simple, taught-in measurement programmes.

- Automatic reading and writing of tool data, base data, work objects, user frames and other calibration data at the touch of a button

- Transparent error measures and quality criteria

- Full measurement logs to reconstruct the condition at each measurement

Software

Choose your individual solution - and upgrade anytime !

tool:in

The aim of the survey is to determine the tool center point (TCP). You get the actual geometric dimensions of the tool in relation to the flange coordinate system, in 3, 5 and 6 dimensions.

base:in

The goal is to determine the transformation from the workpiece to the robot's coordinate system. The software measures fixtures, stations or external stationary tools. High-precision, contactless and automatic.

loop:in

The aim is to measure, optimize and reference the absolute positioning accuracy using the "closed-loop method". You get an accurate model of the robot axes. Suitable for optimization and recovery.

kir:in

The goal is to measure 1- to 5-axis positioners, rotary tables, rotary tilting tables, additional axes or synchronized, coupled, cooperating robots. You get a coordinate system in which the kinematics move.

The aim of the survey is to determine the tool center point (TCP). You get the actual geometric dimensions of the tool in relation to the flange coordinate system, in 3, 5 and 6 dimensions.

The goal is to determine the transformation from the workpiece to the robot's coordinate system. The software measures fixtures, stations or external stationary tools. High-precision, contactless and automatic.

The aim is to measure, optimize and reference the absolute positioning accuracy using the "closed-loop method". You get an accurate model of the robot axes. Suitable for optimization and recovery.

The goal is to measure 1- to 5-axis positioners, rotary tables, rotary tilting tables, additional axes or synchronized, coupled, cooperating robots. You get a coordinate system in which the kinematics move.

Services

Our customer support team is here to help you. Please do not hesitate to contact us.

We can help you find the causes, advise on possible solutions and offer complete solutions with customised measurement programmes and systems. Contact us.

Our experienced team of robotics specialists will work hand in hand with you to efficiently implement cell calibration solutions and train your staff to use the systems.

Complete measurement data logs allow optimal remote support by our experts. Our support is also available for spontaneous problems via e-mail, telephone, video call or on-site.

Interested in LaserLAB? We will be happy to advise you.

Just fill in the form or call us directly.