Gripper testing and calibration with GripLAB

Your robot has caused a collision. You have succeeded in aligning the gripper so that the workpiece fits in the gripper without tension, but neither the pick-up position nor the set-down position, nor the machining points or paths in between are OK because the real workpiece no longer matches the tool data. Adjustment of the tool frame in 6D, including orientations, is required to achieve the exact form fit required on all sides of the gripper.

GripLAB provides you with a quick, automatic check and calibration of the tool frame so that your robot is up and running again in no time.

GripLAB benefits

High accuracy calibration system for 6D gripper or tool frame measurement

Complete 6D measurement of a gripper/part in less than 60 seconds

Fully integrated in the cell and under robot programme control

Automatic transfer of the correction values

Allows gripper measurement without the need for probes or other tools

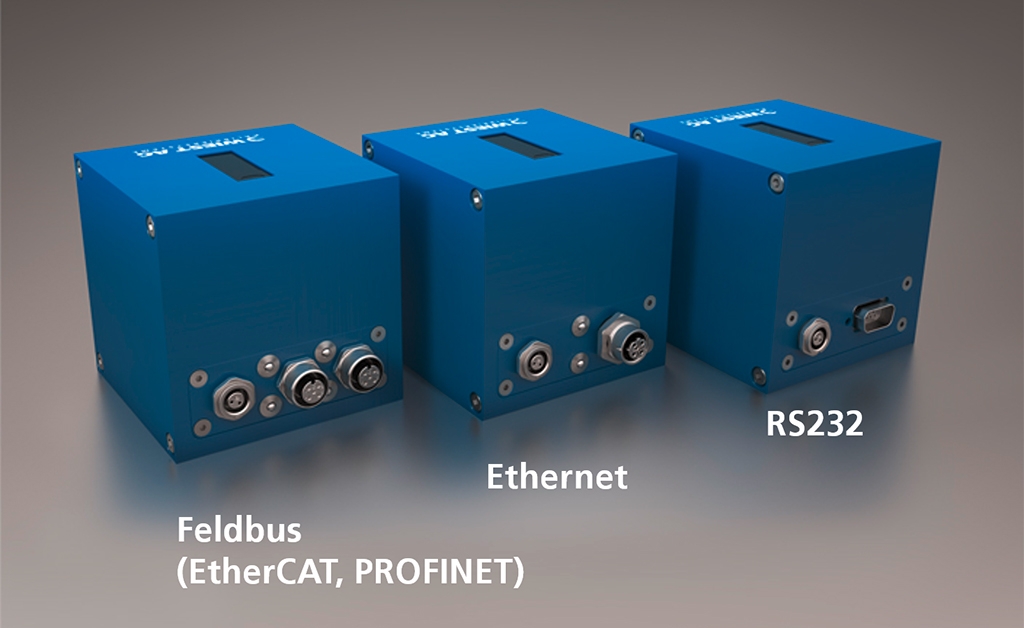

Data communication via Profinet, Profibus, Ethernet or RS232

Fast and efficient recovery of gripper positions on all stations

Calibration accuracy better than 0.2 mm

Complete failure chain from flange to component captured in one step

TCP correction (in 6 dimensions) in the robot controller

High accuracy calibration system for 6D gripper or tool frame measurement

GripLAB - The 6D expert for automated control and rapid calibration of grippers and components

GripLab enables complete 6D measurement of a gripper or component, including orientation, in less than 60 seconds. The system can take control measurements during operation, detect any positional deviation and correct it automatically. Or to get cells up and running again in the shortest possible time after a collision. The system captures the entire possible error chain from the robot flange to the component in one step, thereby increasing the process reliability and availability of handling cells.

- 6D measurement (3D coordinates, 3D rotation angle)

- Calibration accuracy < 0.2 mm

- Data communication via Profinet, Profibus, Ethernet or RS232

Hardware

GripLAB is a compact measuring system with precise laser measurement technology.

It is mounted in the robot cell by means of an adapter plate that is included in the scope of delivery. Connection to the robot controller is via either an RS232 or Ethernet interface. Optional connection via fieldbus, ProfiNET, DeviceNet or EtherCat.

- Mounting in the robot's work area

- Measurement distance: average measurement distance 120 mm (+/- 60 mm measurement range)

- Dimensions: W 85 mm, D 85 mm, H 85 mm

High accuracy calibration system for 6D gripper or tool frame measurement

GripLAB - The 6D expert for automated control and rapid calibration of grippers and components

GripLab enables complete 6D measurement of a gripper or component, including orientation, in less than 60 seconds. The system can take control measurements during operation, detect any positional deviation and correct it automatically. Or to get cells up and running again in the shortest possible time after a collision. The system captures the entire possible error chain from the robot flange to the component in one step, thereby increasing the process reliability and availability of handling cells.

- 6D measurement (3D coordinates, 3D rotation angle)

- Calibration accuracy < 0.2 mm

- Data communication via Profinet, Profibus, Ethernet or RS232

Hardware

The GripLAB is a compact measuring system with precise laser measurement technology.

It is mounted in the robot cell by means of an adapter plate that is included in the scope of delivery. Connection to the robot controller is via either an RS232 or Ethernet interface. Optional connection via fieldbus, ProfiNET, DeviceNet or EtherCat.

- Mounting in the robot's work area

- Measurement distance: average measurement distance 120 mm (+/- 60 mm measurement range)

- Dimensions: W 85 mm, D 85 mm, H 85 mm

Process

How the GripLAB calibration process works

GripLAB measures a gripped component or the gripper of a handling application in less than a minute. If the control measurement exceeds a specified tolerance, the tool data can be corrected directly in the control. GripLAB can be used during ongoing operation. In this way, creeping deterioration of the gripping process can be detected and corrected at an early stage – before a collision occurs.

The calibration process is demonstrated in the adjacent video.

The individual process steps

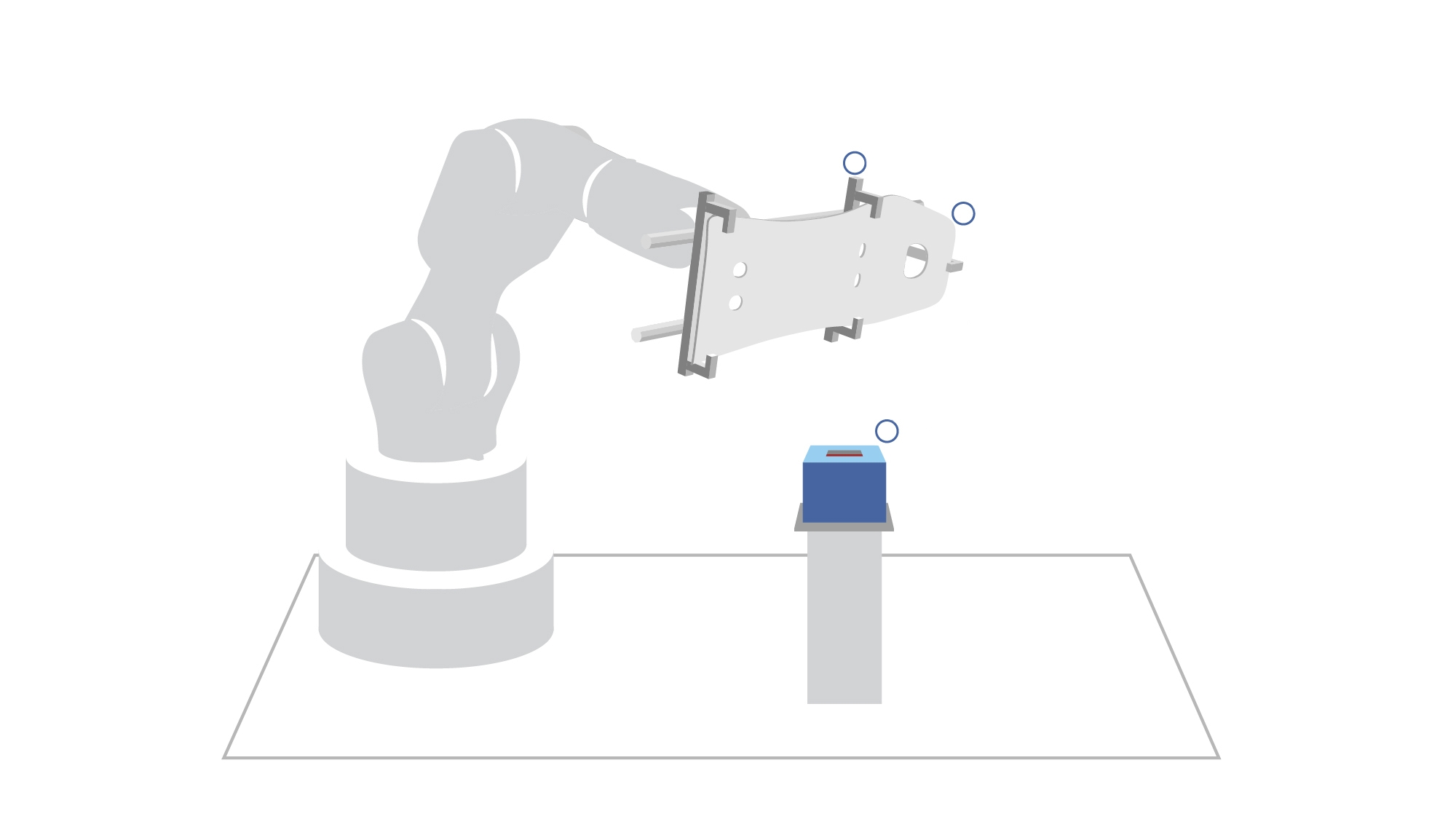

Initial situation

The initial commissioning of GripLAB after installation in the robot cell involves a simple motion programme with nine measuring points.

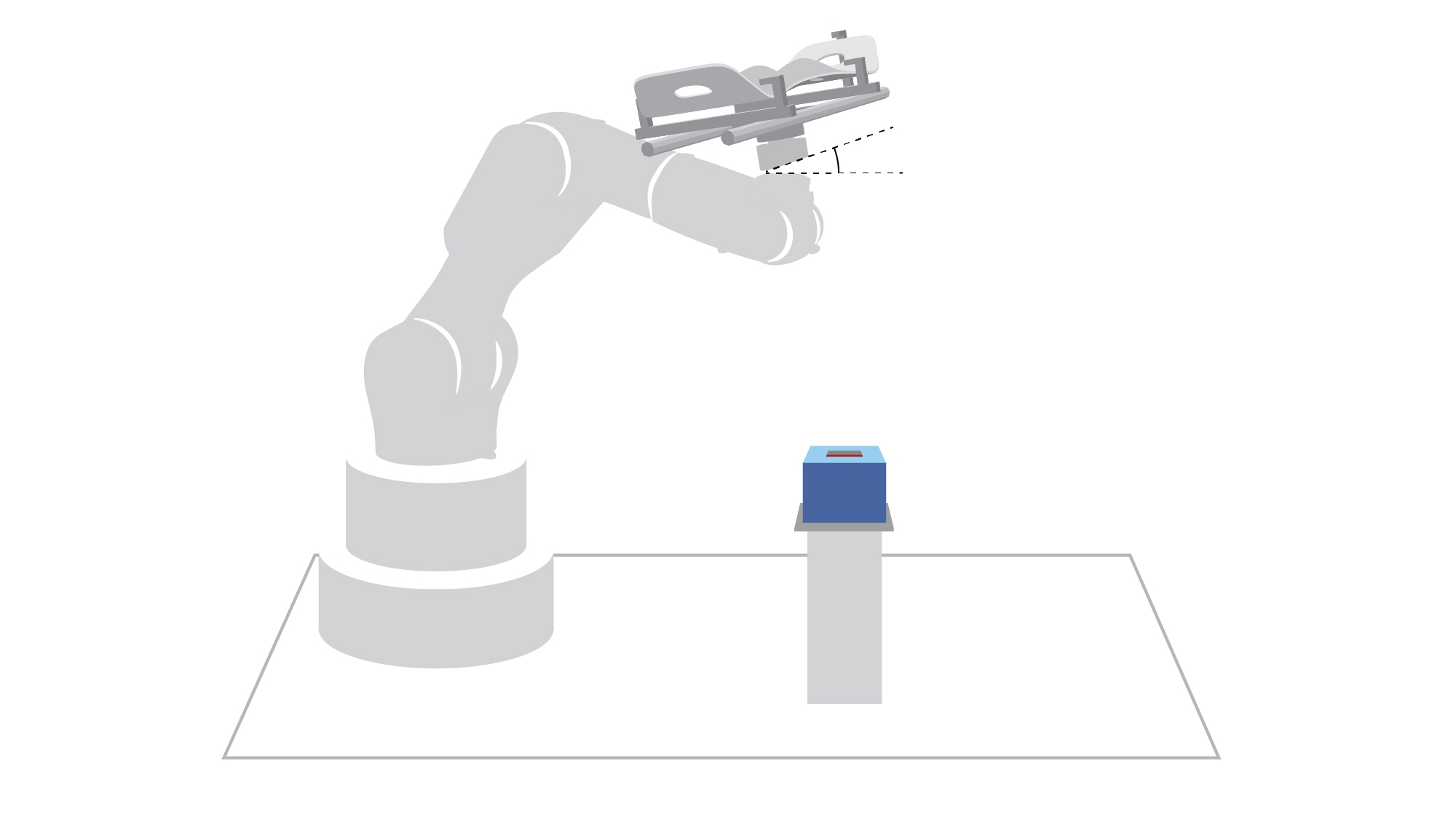

Inspection

After a crash, the test shows that the gripper is misaligned. No additional software installation on the robot controller is required.

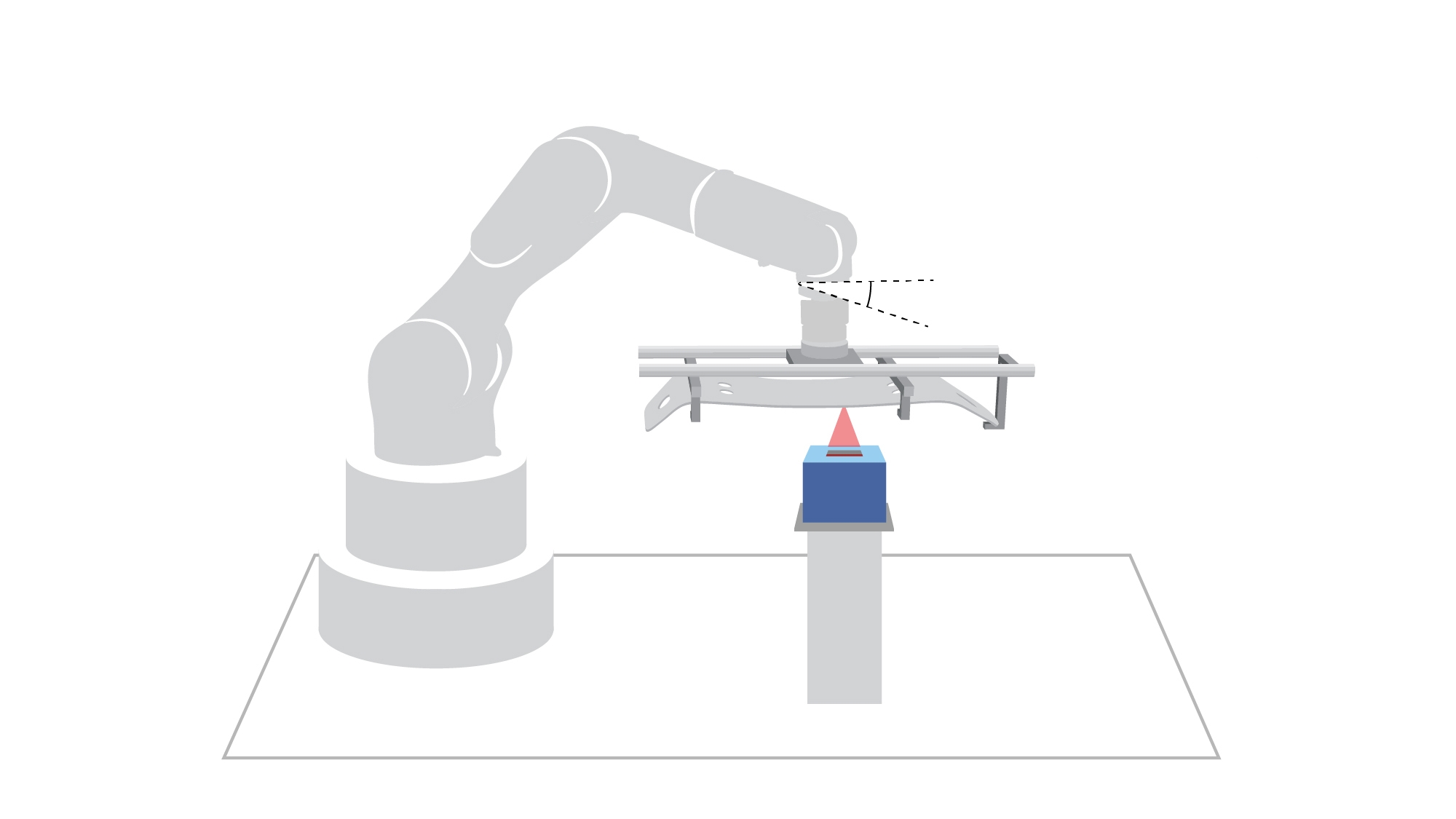

Measurement

Automatic measuring of the gripper is done by running the moving programme.

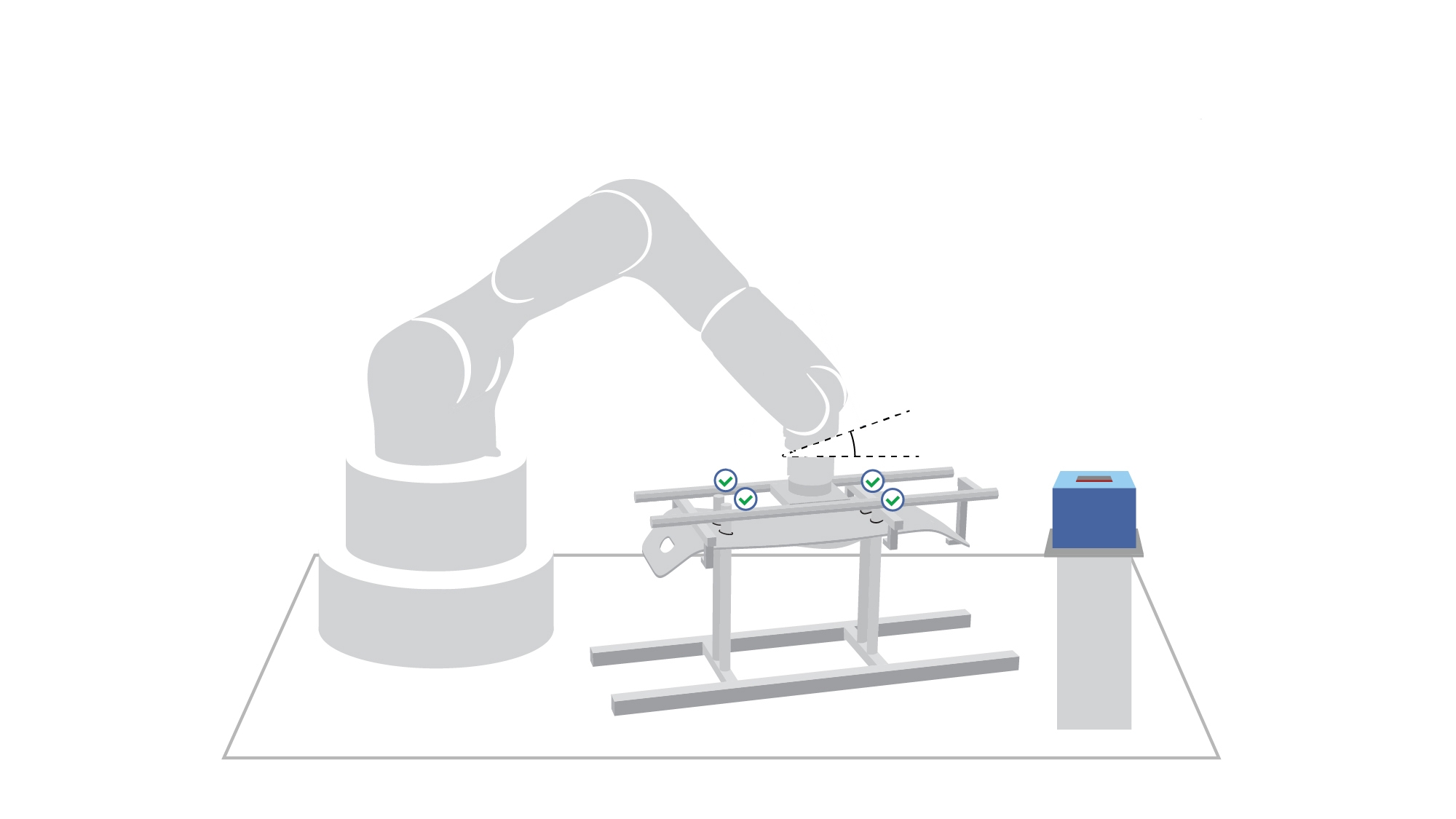

Calibration

Calibration of the gripped part. After automatic transfer of the corrected tool data, the gripping process is precise again.

Plant engineer, robotics, automotive OEM

"GripLAB saved us two days of night work when changing grippers, so it paid for itself within a week of installation".

Plant engineer, robotics, automotive OEM

"GripLAB saved us two days of night work when changing grippers, so it paid for itself within a week of installation".

Compatibility

GripLAB is available for

No additional hardware or software is required. Other robot controllers with interface (RS2323, Profibus, Profinet, EtherCAT, Ethernet) can be integrated.

Software

Fully integrated or via fieldbus You have the choice

Full integration of GripLAB into the robot controller

In addition to the standard Ethernet and RS232 connections, GripLAB can also be integrated into your fieldbus system using a protocol converter.

Services

Our customer support team is here to help you. Please do not hesitate to contact us.

We can help you find the causes, advise on possible solutions and offer complete solutions with customised measurement programmes and systems. Contact us.

Our experienced team of robotics specialists will work hand in hand with you to efficiently implement cell calibration solutions and train your staff to use the systems.

Complete measurement data logs allow optimal remote support by our experts. Our support is also available for spontaneous problems via e-mail, telephone, video call or on-site.

Interested in GripLAB? We will be happy to advise you.

Just fill in the form or call us directly.