Machining of castings with many path points

In a system for deburring castings, point misalignments occur time and again, resulting in extensive re-teaching.

Wiest advantages

Customer benefits

The plant was back in production immediately after the move. By investing in Wiest LaserLAB, the customer has avoided at least one week of production downtime.

The handling process is secured. In the event of a new point offset, the tool measurement was repeated and the changed tool data was sent to the control. The process could be continued without any re-teaching.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

Cell description

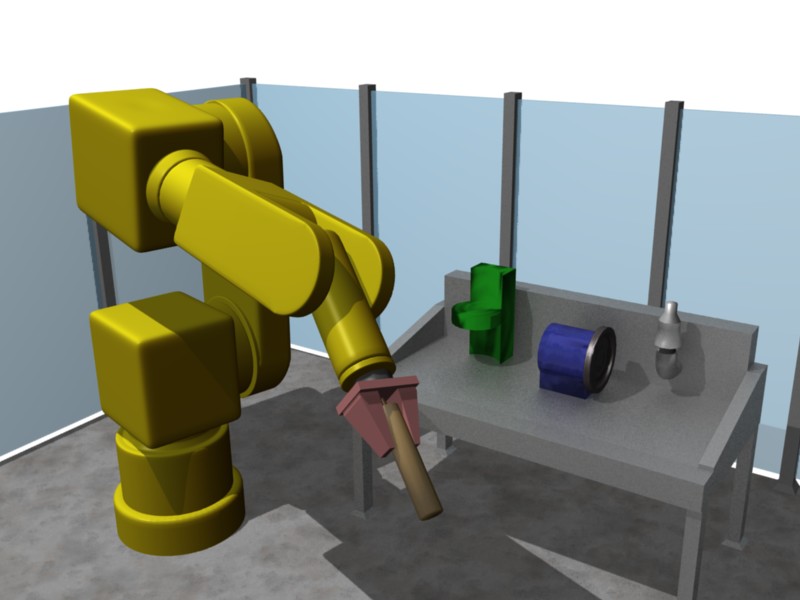

In the cell, a KUKA robot picks up KR castings and drills, deburrs, brushes and grinds them on several stationary tools. In order to move the castings along the tools, paths with a very large number of points are required. In addition, two different castings are being machined on the line, doubling the number of robot programmes.

Task

The gripper, which is used to guide the castings along the machining stations, is one of a kind. There is no spare gripper. Even after a minor crash, or after long periods of production, a point shift would still occur. This regularly resulted in extensive manual re-teaching over several shifts.

The cell should also be moved. The move would have required the programmes to be re-taught. Due to the number of points and programmes to be readjusted, the customer expected a lengthy production stoppage.

Implementation

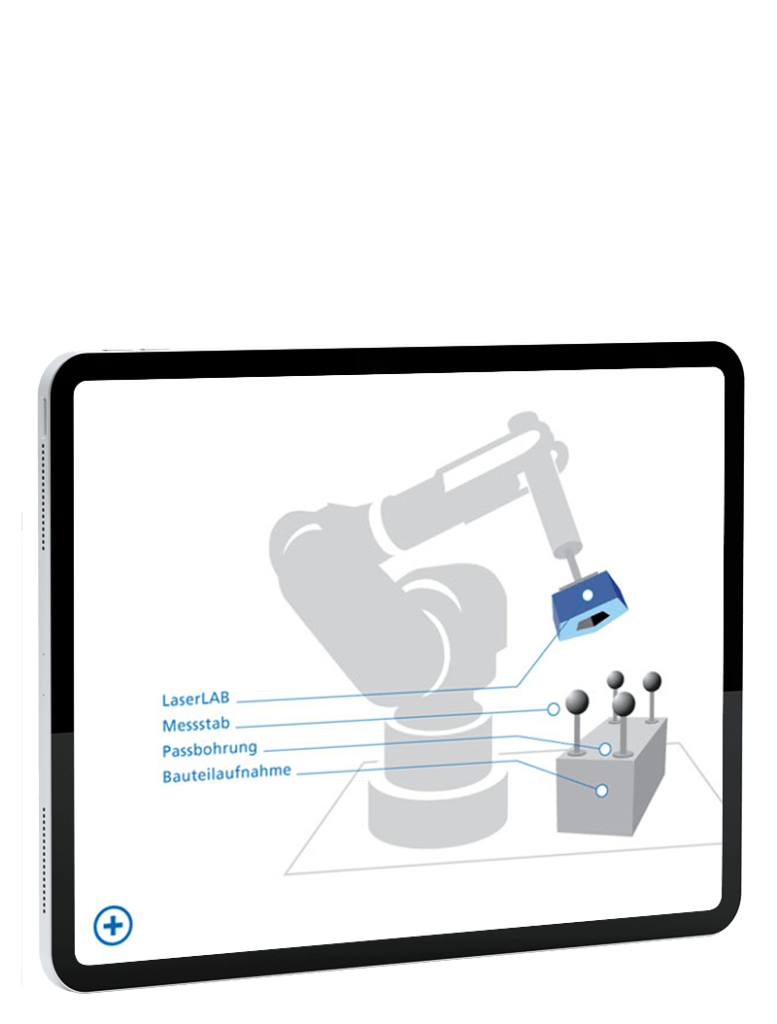

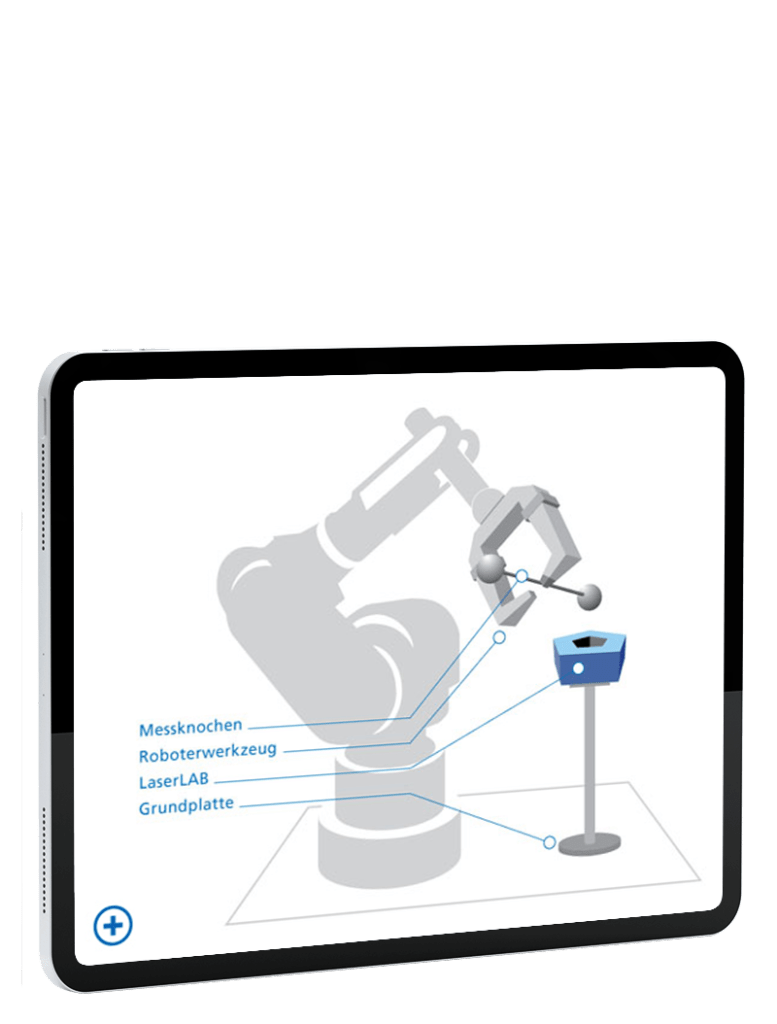

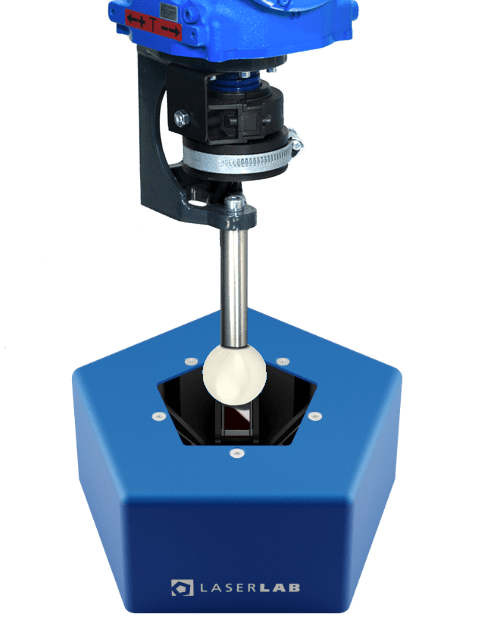

Two master parts were produced and the actual state of the two tools was measured using LaserLAB and tool:in. In addition, measuring rods were attached to the base plate for the processing machines and the position of the base plate was measured using base:in.

The cell was then moved and measured again with LaserLAB. The new geometric states were transferred to the robot at the touch of a button.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order