Precise thrust direction for milling applications

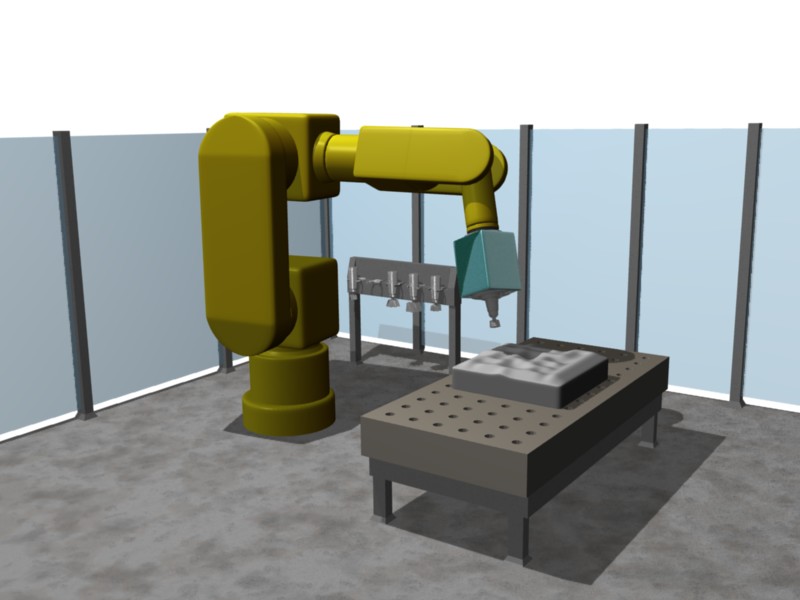

A milling robot is used to produce parts using the rapid prototyping method.

Wiest advantages

Customer benefits

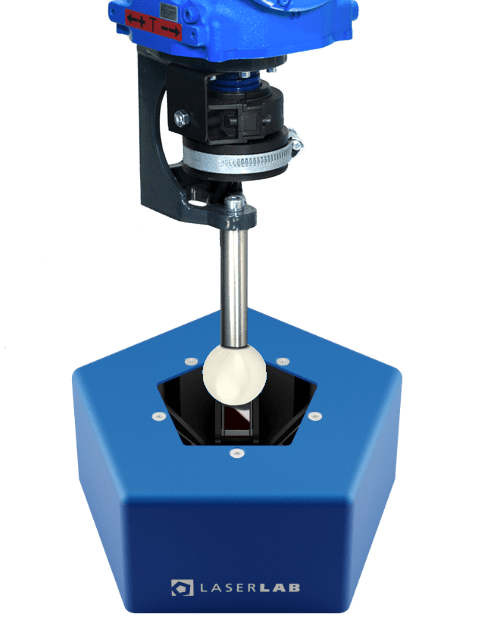

Using a LaserLAB and tool:in, the thrust direction of the milling tool was determined with high precision within a few minutes. Manual alignment of quaternions is a thing of the past.

Thanks to precise knowledge of the tool and the object, the customer is now able to carry out rapid prototyping with the milling robot.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

Cell description

The customer operates two lines for seam sealing, underbody protection and cavity preservation of car bodies. A total of 32 Fanuc M16 and M-710 robots are used on linear units. PVC is applied with SCA Schuker spray lances.

Task

The customer wants programmes that have been programmed on one line to also run on the second line without having to make up for lost time. The reason for this is an emergency strategy: if a robot fails, another one will take over.

Implementation

Products

These Wiest products were used:

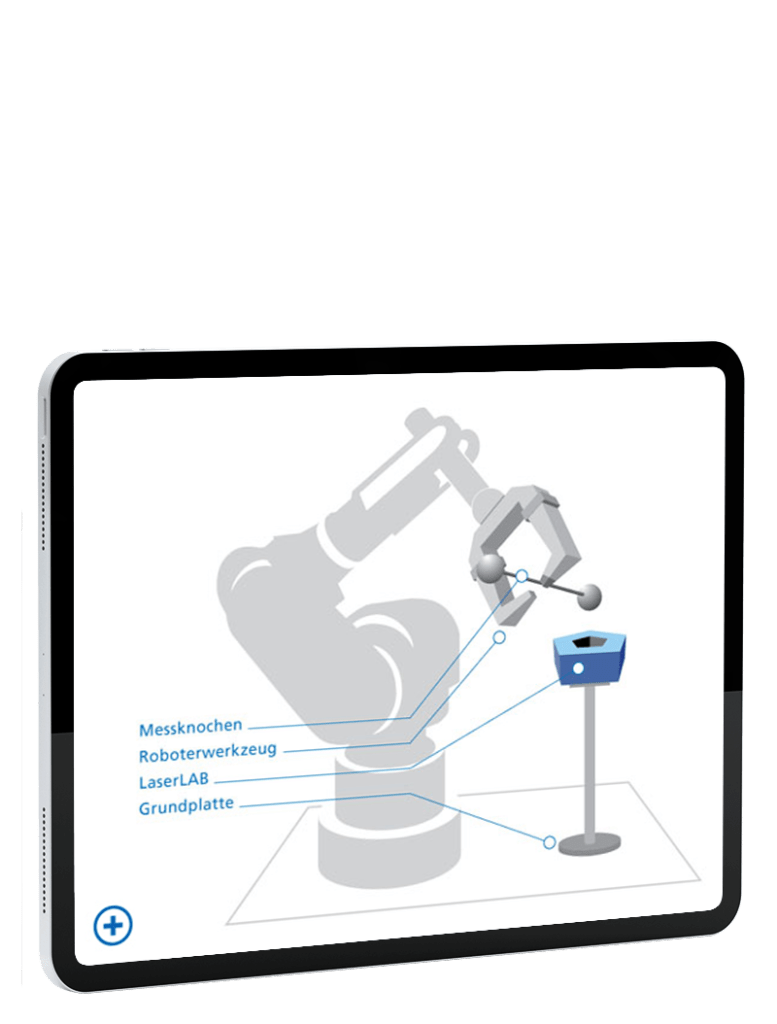

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order