Cloning of production lines

To avoid having to repeat the complex measurement for a second cell for deburring turbine blades, the robot cell is to be cloned.

Wiest advantages

Customer benefits

The programmes of the master cell were easily transferred to the cloned cell.

At the same time, both installations could be secured by measuring them. Replacement of fixed cutters can be geometrically mapped by re-measuring with LaserLAB. This ensures that the milling programmes function correctly.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

Cell description

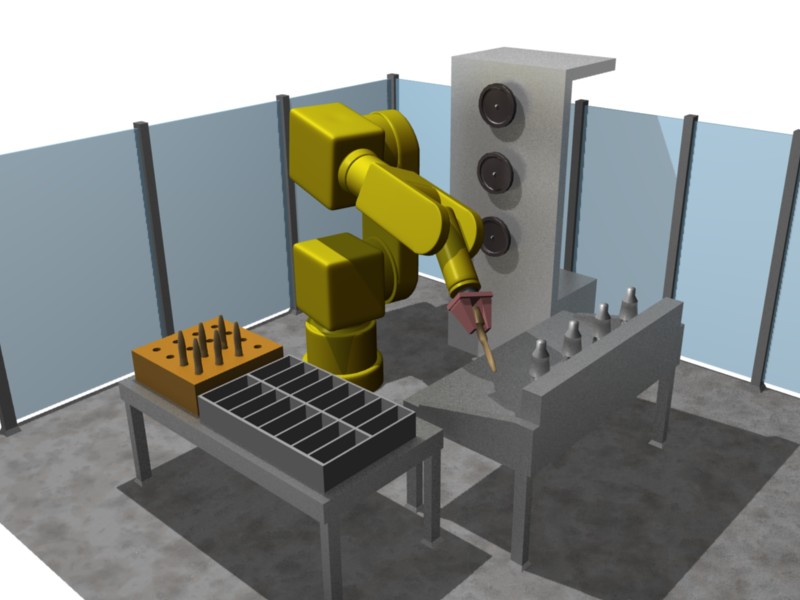

In the customer’s robot cell is an ABB IRB 4400, which deburrs turbine blades for aircraft engines. The parts are gripped, placed in a positioning station and gripped again. The robot then deburrs the parts at a milling station consisting of several fixed cutters. The robot then moves the parts to a brushing station as the final processing step. Once the parts are finished, they are placed in a magazine.

Task

The robot programme for deburring turbine blades is extremely difficult to create. The key criteria are the specific radii that the blades must have. In the end, an acceptable result could only be achieved by measuring the blades and then reprogramming them in tenths of a millimetre. This process had to be repeated several times.

To avoid having to repeat this process for the second milling cell, the customer ordered the robot cells to be cloned.

Implementation

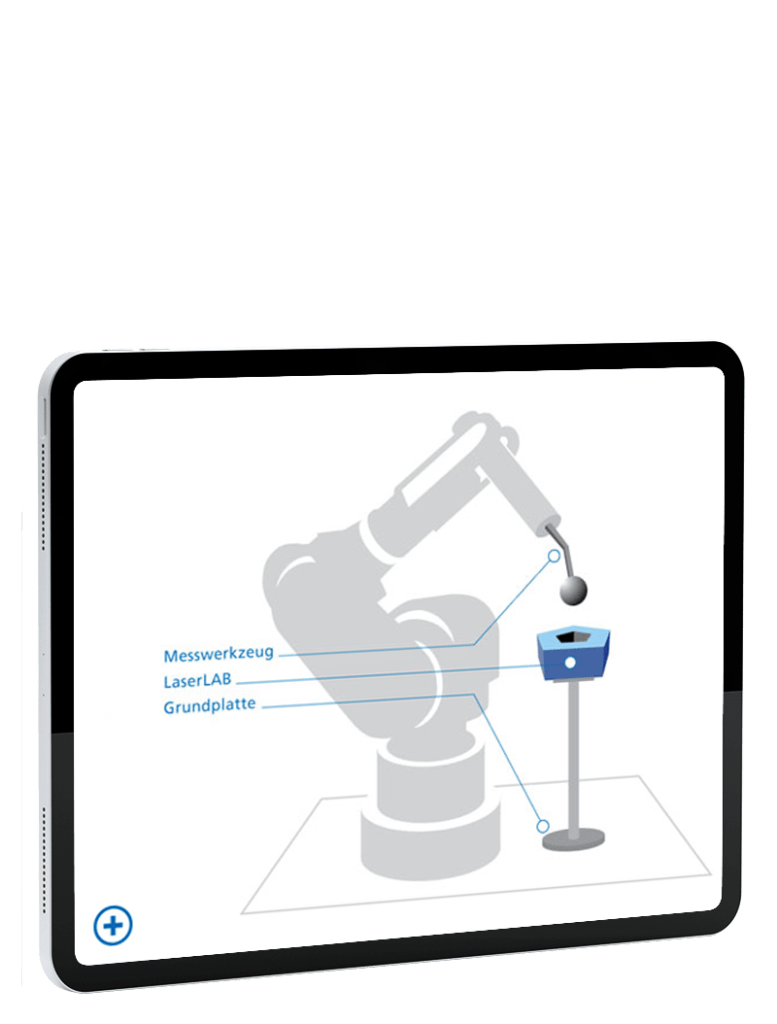

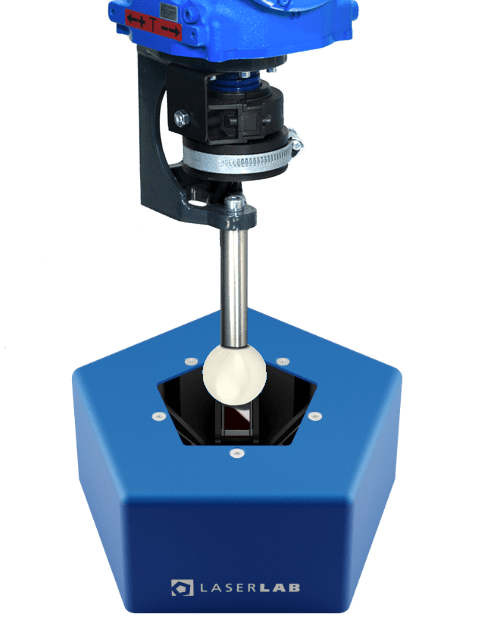

The robot was equipped with a manual tool change system. An adapter plate was supplied that could be fitted with either a single measuring rod for robot calibration with loop:in or with LaserLAB for measuring the cutters.

For the cutters, a measuring rod with a 6 mm pin was made to hold the chuck. The measuring rod is designed so that the centre of the ball coincides with the tip of the cutter.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 480 44 99 - 0

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order