Seam sealing and underbody protection

When replacing wear parts, the robot programs must be reteached

Wiest advantages

Customer benefits

Problems associated with changing a spray lance are completely eliminated as only the three tools need to be re-measured. This only takes 20 to 30 minutes.

In addition, the robots were measured with absolute precision by means of loop:in. This gives the customer the option of offline programming.

The problems experienced in the past with the old KR6 robots have finally been eliminated. Once a point offset has been diagnosed, the robot is measured with loop:in and then the tools are measured with tool:in. This eliminates the possibility of point offset.

Offline programming possible

A point offset is excluded

Absolutely accurate measurement through loop:in

No problems with old KR6 robots

Case

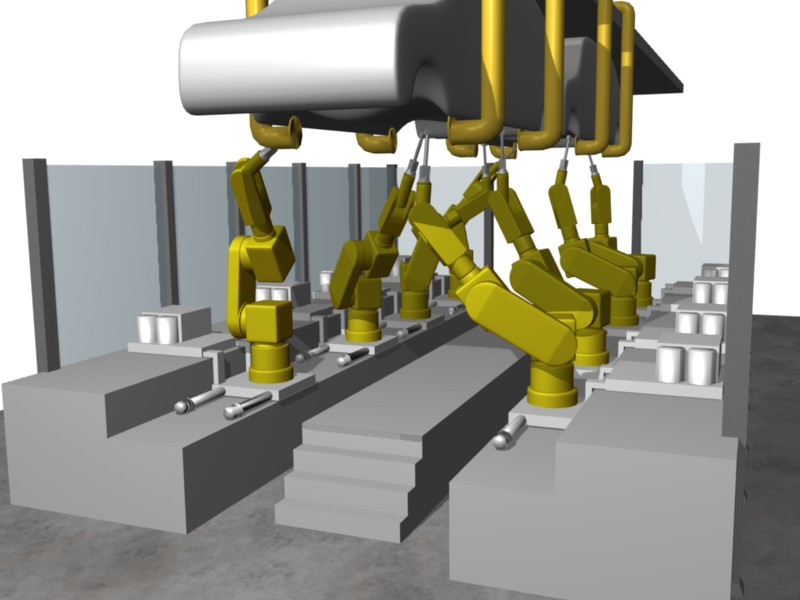

Cell description

The customer has a production line in their paint shop where PVC is applied to the underbody of the car body for underbody protection. There are 12 KUKA KR16 robots on linear axes in the line, each equipped with SCA Schuker spray lances with three nozzles. The seam sealing line has four old Kuka KR 6 robots that can only be adjusted via Nonius.

Task

The spray lances are wearing parts that are replaced at irregular intervals. Due to the tool change, the robot programmes are no longer accurate and have to be reprogrammed.

In addition, the customer wants to program the robots offline more in the future and needs absolutely accurate robots for this. However, due to their age, the existing robots can no longer be measured with absolute precision by the manufacturer.

Implementation

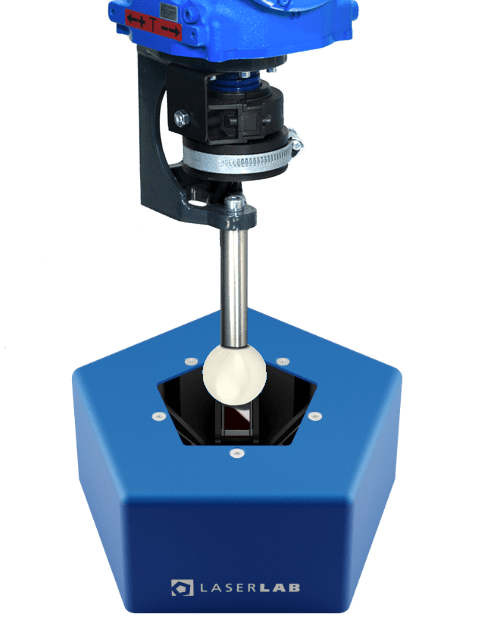

The measuring triangle was used to measure the nozzles. With an appropriate adaptation, it was attached to the lance by means of two screws in place of the nozzle. The measuring triangle has the advantage of being able to determine not only the direction of impact of the tool or the direction of the PVC jet, but also the X-direction of the tool, which plays a role in flatstream, as opposed to the omnidirectional jet.

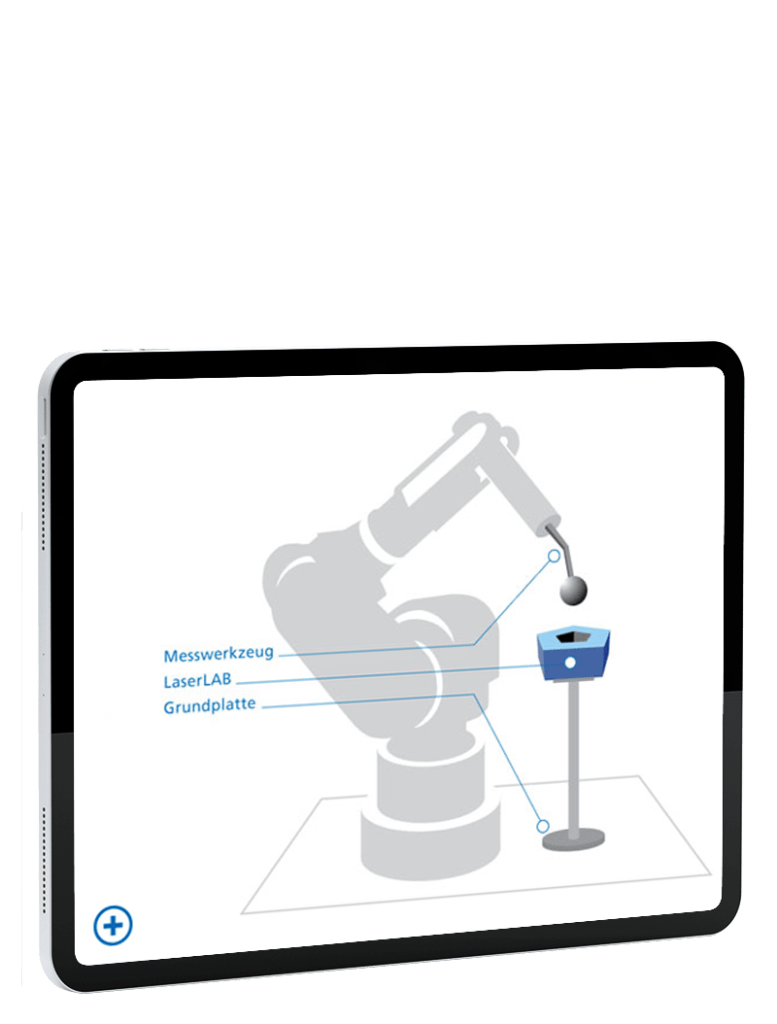

When measuring the robots using loop:in, the linear axes were also included. The linear axis is moved while the robot holds its TCP in the LaserLAB. The result of the calibration also provides, among other things, the mounting error of the robot on the linear axis.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order