Calibrating a vision system into car frame

A line for applying underbody protection and sealing seams to car bodies should be able to run in new vehicle models without external service providers.

Wiest advantages

Customer benefits

The customer is now able to integrate new vehicle models into its production line without external support.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

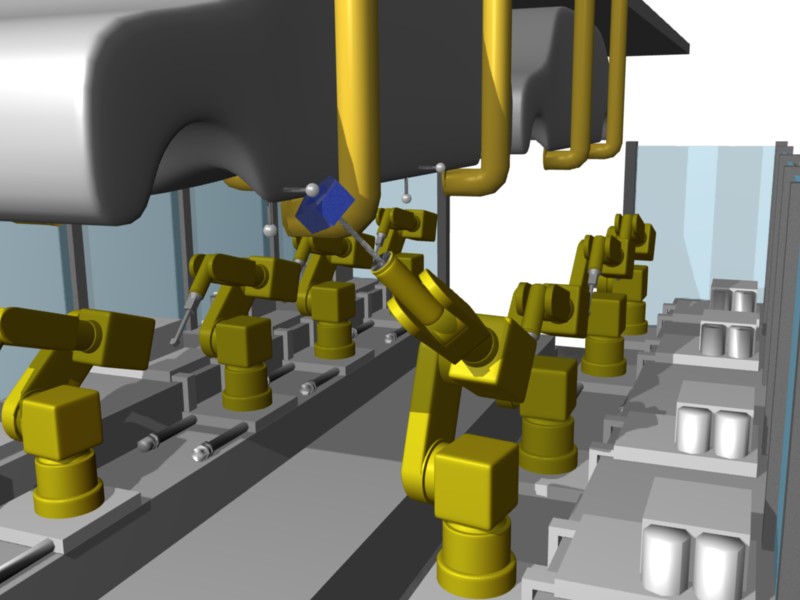

Cell description

In the customer’s paint shop, 12 KUKA KR 16 robots apply the underbody coating and a further 6 KUKA KR 6 robots apply the sealing seams to the car bodies. The car bodies are measured with an ISRA measuring system when they enter the cabin. The offset of the current body to the zero body is determined and sent to the robot controllers as a basic correction.

Task

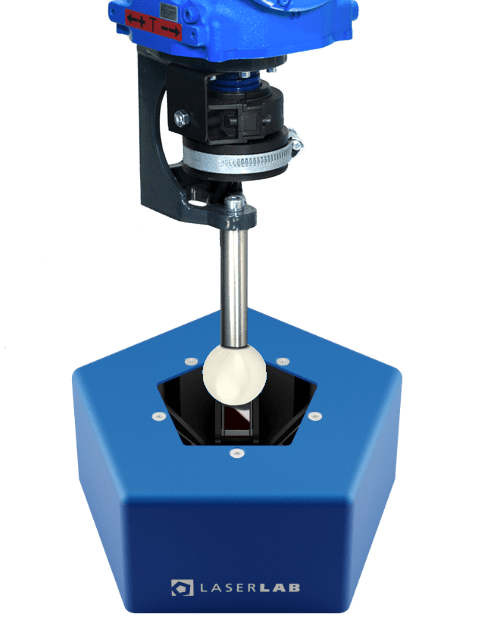

A new model must first be set up in the ISRA system before it can be integrated into the line. Up to now, the relationship between the vehicle and the robot has been measured using a laser tracker. An external service provider was necessary for this work. In the future, the customer wants to carry out this work on his own with the help of the LaserLAB and the base:in software.

Implementation

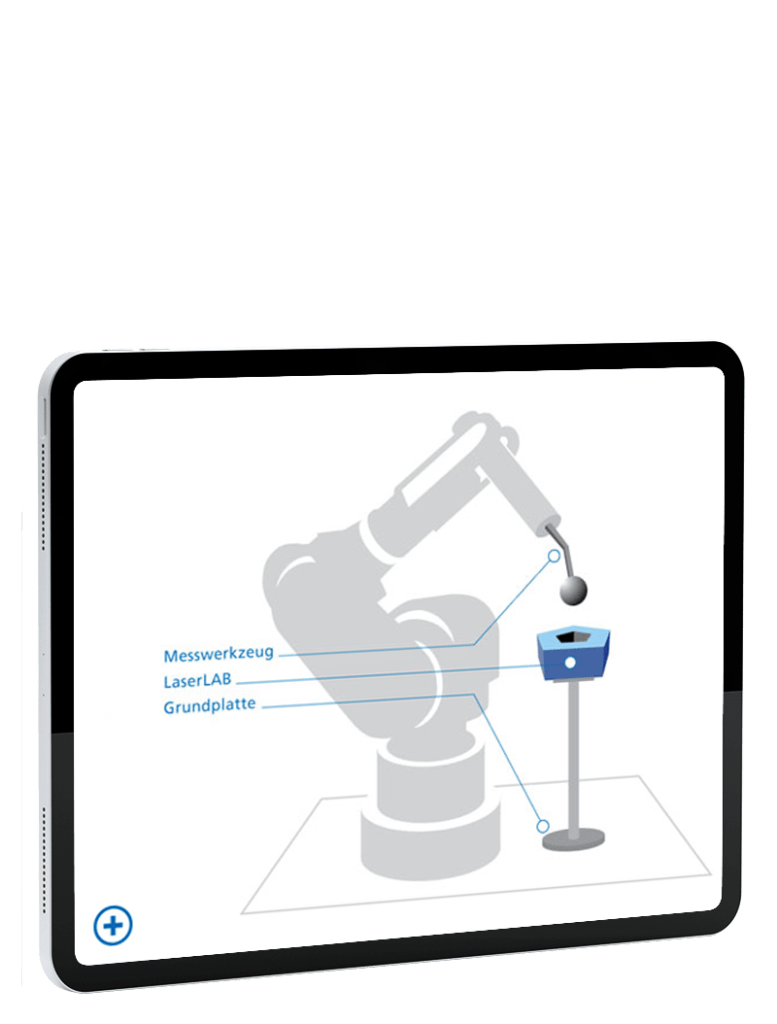

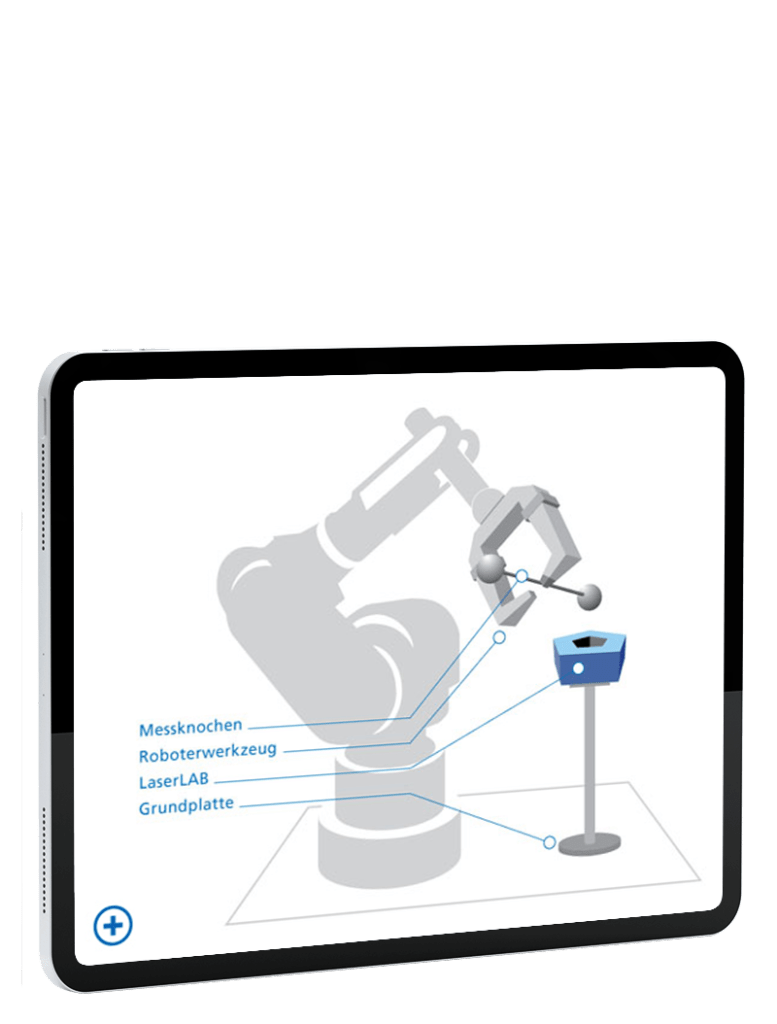

Four measuring balls are attached to the car body with corresponding adapters. The positions of these balls are measured in the measurement house relative to the vehicle zero point. The measuring body is then moved into the production cell and measured with each robot in turn. The result is the base transformation body – robot. This is transmitted to the robot. The measurement body is measured with the ISRA system at the same position where it was measured with the robots and stored as a so-called zero measurement. In the future, the ISRA system will determine the offset of the current body to the zero body and perform a base correction of the robots.

Products

These Wiest products were used:

LaserLAB

The ultimate all-in-one solution for robotic cell measurement and calibration tasks

Technical support

Contact our support team with any technical questions.

+49 (0)821 123 456

Technical support

Contact our support team for all technical questions

+49 (0)821 123 456

More cases

Here you can find more cases on this topic

Fast commissioning of offline programmes

Fast commissioning of offline programmes In order