Fast commissioning of offline programmes

Fast commissioning of offline programmes In order to avoid having to recreate robot programmes created offline, it is necessary to measure the robots with absolute precision and determine tool and frame data accurately. Wiest advantages Customer benefits The time required to re-teach offline generated programmes has been minimised. The goal of a very short commissioning […]

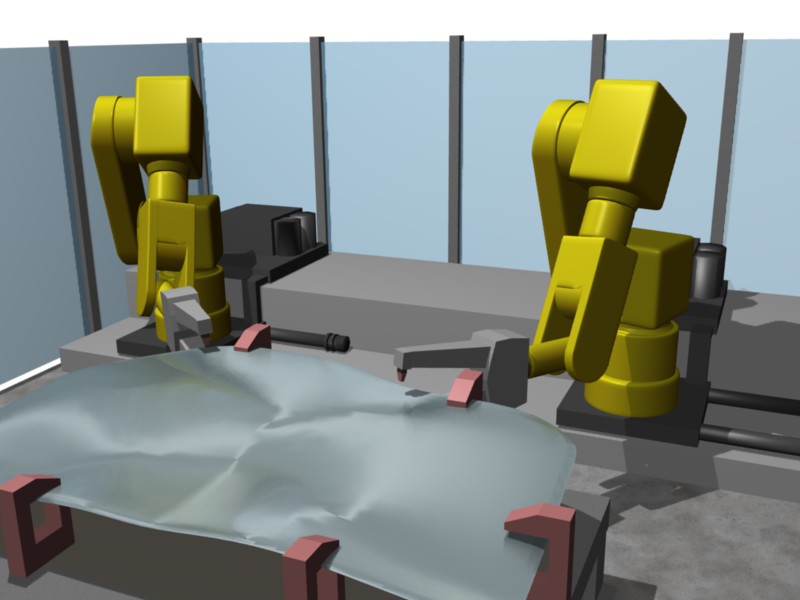

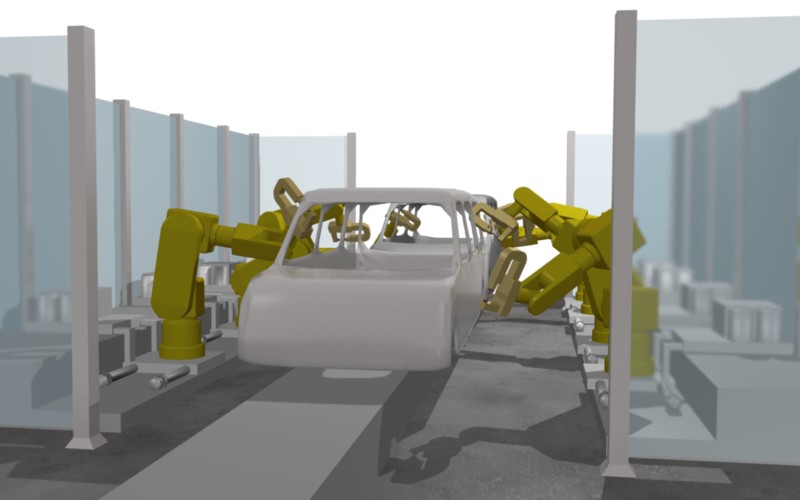

Spot welding in body-in-white

A large car manufacturer operates several welding lines for car bodies. Kuka KR125 robots and Comau H4 with spot-welding guns are used.

The special feature of the production line is that a large number of different models are produced on the same lines, and new models need to be introduced with as little interruption to the running line as possible.

To make matters worse, re-teaching had to be done for all models. However, these were not available at the time of the work. The model may not have appeared until the next shift. If you forgot to stop the line and adjust the robot programmes, the crash happened again.

In addition, the task was to ensure that the Comau robots could be exchanged for new ones. There is no repeatable and reproducible mastering procedure for this type of robot.