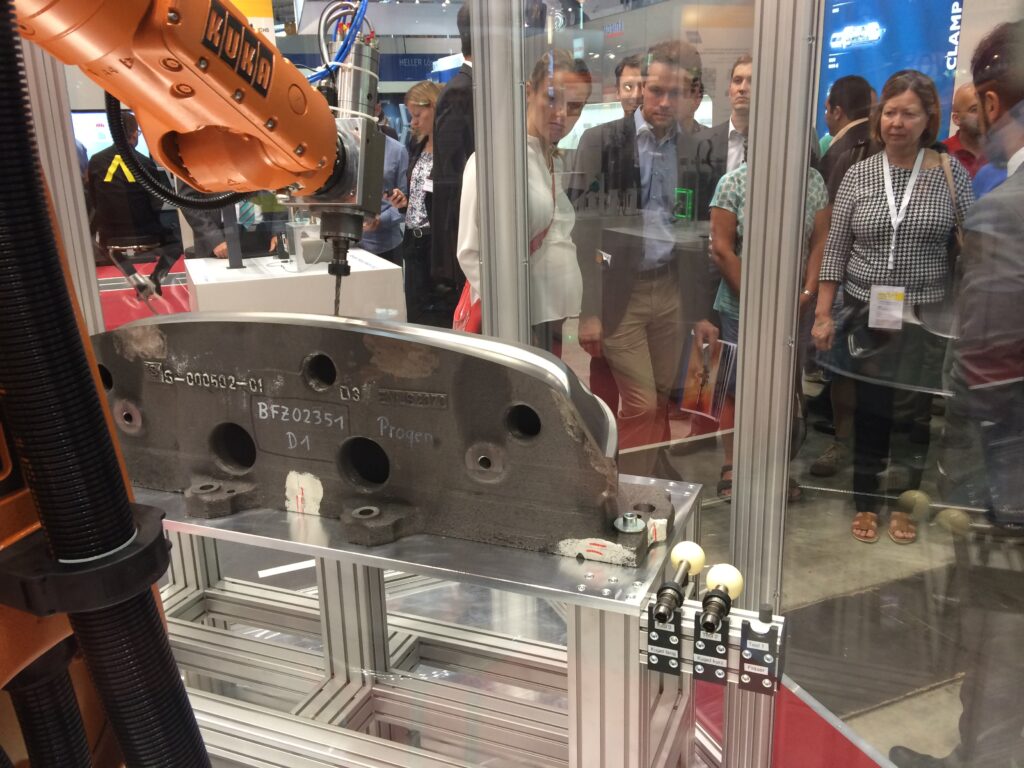

The achievable accuracies of standard industrial robots are still magnitudes above those of machine tools, despite calibration. Nevertheless, calibration opens up the use of industrial robots in some areas of metal processing, where an accuracy of approx. +/-0.3 mm is sufficient. Applications include milling of free-form surfaces, deburring of gray cast iron, drilling or buildup welding.

The calibration consists of two parts:

- Absolutely accurate calibration of the robot directly in the manufacturing cell with original load in the working area of the robot.

- Second tool measurement of the cutter in 5 dimensions by measuring the TCP including the push direction.

The LaserLAB from Wiest AG is a portable and compact robotic measuring system for fast and flexible use directly in the production cell. The system is integrated into the controllers of all common robot manufacturers.

In practice, the system is used on one hand to increase the accuracy of the robot application – especially during reorientations – and on the other hand to quickly and reliably restart the application in case of maintenance.