Fast commissioning of offline programmes

In order to avoid having to recreate robot programmes created offline, it is necessary to measure the robots with absolute precision and determine tool and frame data accurately.

Wiest advantages

Customer benefits

The time required to re-teach offline generated programmes has been minimised. The goal of a very short commissioning time was also achieved.

In addition, the calibration revealed that the control cabinets of the two robots were reversed and therefore the master data of the two robots was incorrect. A fatal error that would have gone undetected without measurement. In the future, the robots can be mastered automatically at any time.

Integration on the second line without reteaching

Increase availability

Prevention of downtime

Shortening the commissioning

Case

Cell description

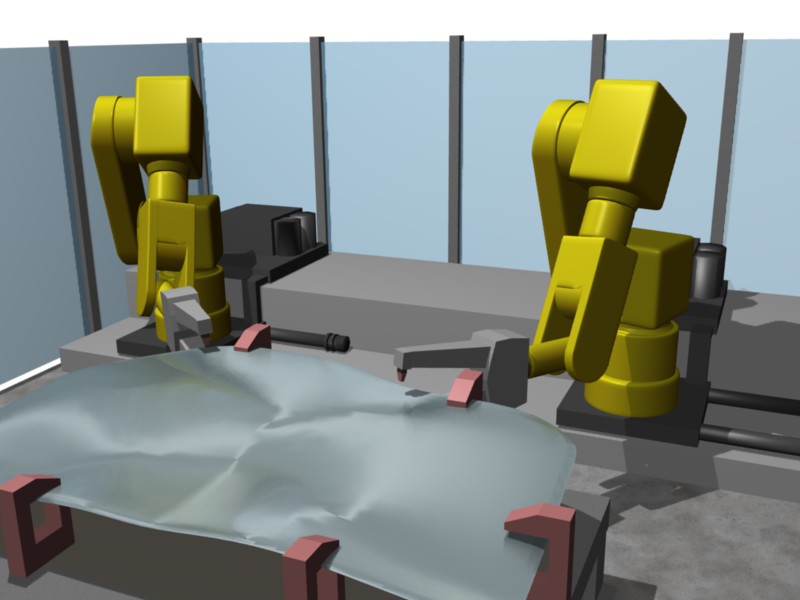

The production line uses two Fanuc R2000iB/165s on a linear axis for spot welding. The cell also has a gripper station for tool change. In the plant, sheet metal body parts are joined and welded by the robot. The cell itself is designed to be universal, so that it can produce a variety of different parts in the future by replacing fixtures and importing new robot programmes generated off-line.

Task

During the Christmas period, the cell was to be used to automate manual workstations. With only two weeks available for the entire commissioning process, the cell had to be pre-programmed offline to allow a direct transition to production. In order to minimise the need to re-teach the programmes created offline, it was necessary to measure the robots with absolute precision and to determine the tool and frame data accurately.

Implementation

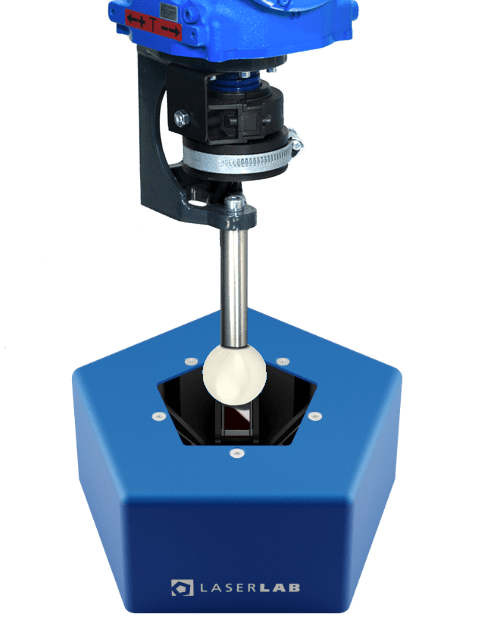

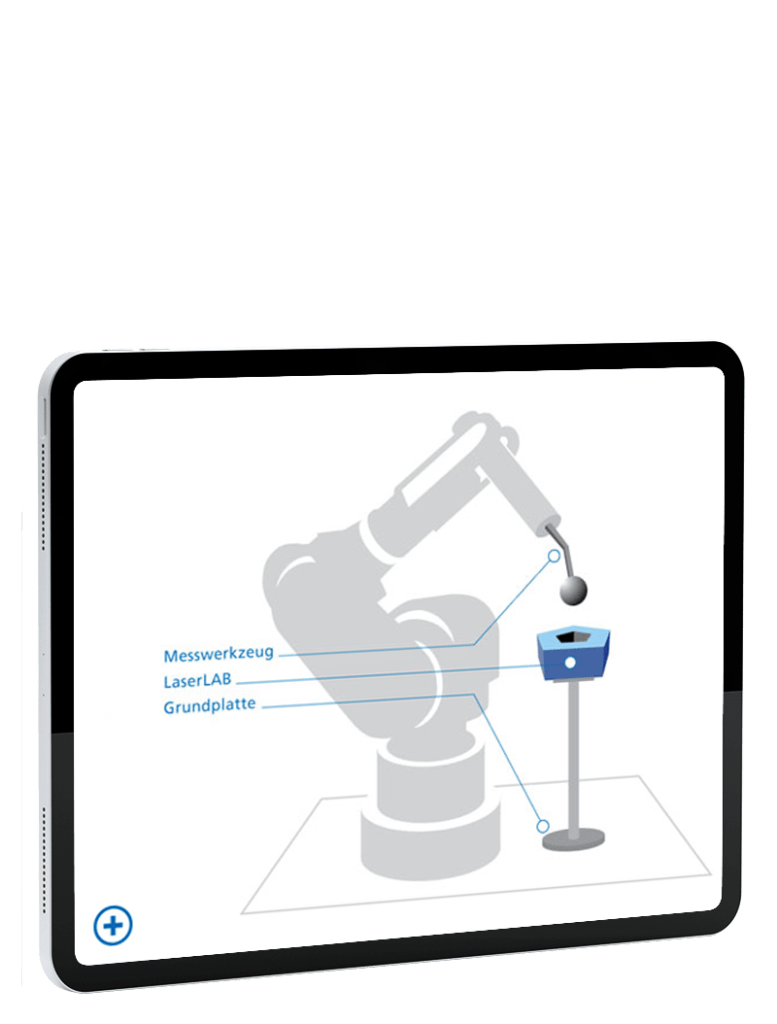

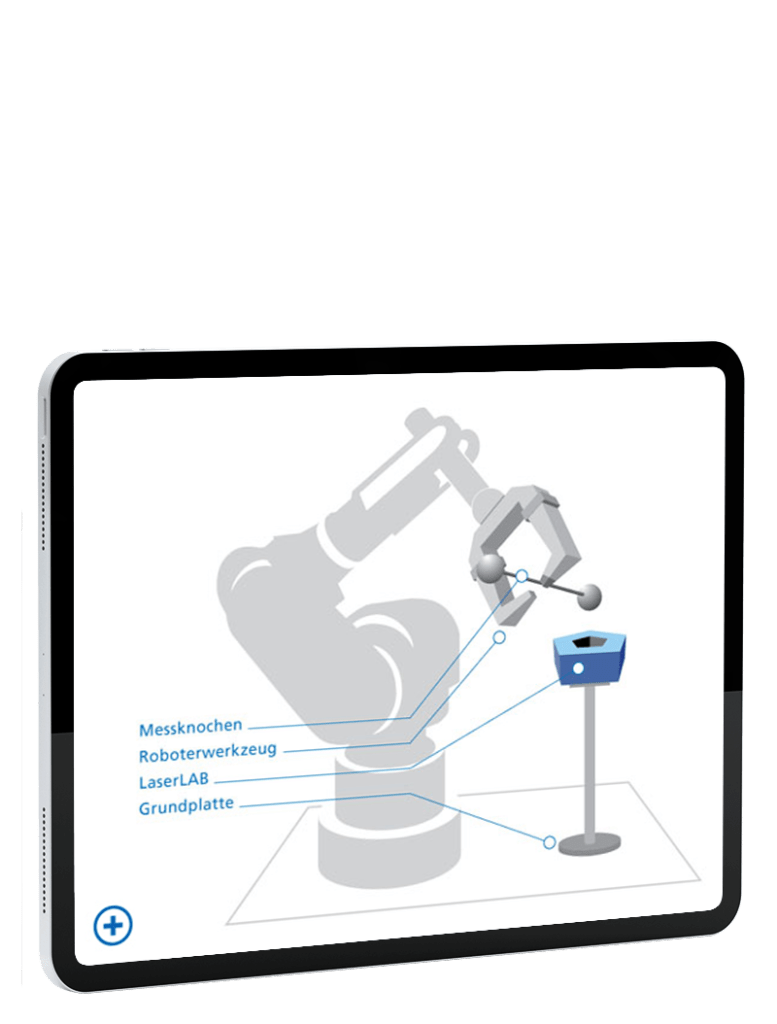

The robot and the linear axis were measured with absolute precision using the loop:in software. For the further measurement of the cell, a universal master part was created that could be picked up by any fixture. The positions of the spheres were measured with a FARO measuring arm in relation to the vehicle’s ZERO coordinate system. This data was then used by LaserLAB and tool:in to determine the transformation of the fixture (vehicle zero) and the robot/linear axis system.

Products

These Wiest products were used: